Warping a rigid heddle loom can be quite daunting when you’re just starting out, but with a little bit of practice and some simple tips to follow, it doesn’t need to be a headache!

I actually love direct warping my rigid heddle loom, I find it so quick and easy compared with indirect warping.

*This post contains affiliate links. For more information, please see my disclosure policy.

What is direct warping?

When you purchase a rigid heddle loom, it should come with a warping peg and clamp. This peg will allow you to start making your warp directly on your RH loom, rather than having to make the warp on a warping board or mill first and then transferring to the loom.

You use the peg to measure out and hold your warp, while the other end is tied on or looped to the back apron rod of the loom. The added bonus here is that you save time by doing part, or all (depending on your yarn and project) of your threading at the same time as the warping. Efficiency at it’s best!

While warping a rigid heddle loom is fairly straightforward, like anything new, it will take some getting used to. Today I have 2 tips to share that are easy to learn but will help you to have a more positive warping experience.

Tip 1 : Use more than one peg

Although your loom will only come with one peg and clamp, you can purchase more separately.

Doing this has a couple of benefits.

- Waste efficiency – If all of your warp threads are travelling to just one central point, some threads will travel further than others. You will find that, when you take all your warp threads off the peg, ready to thread, you will need to cut them all to an equal length for ease of threading and tying on, which creates more waste.

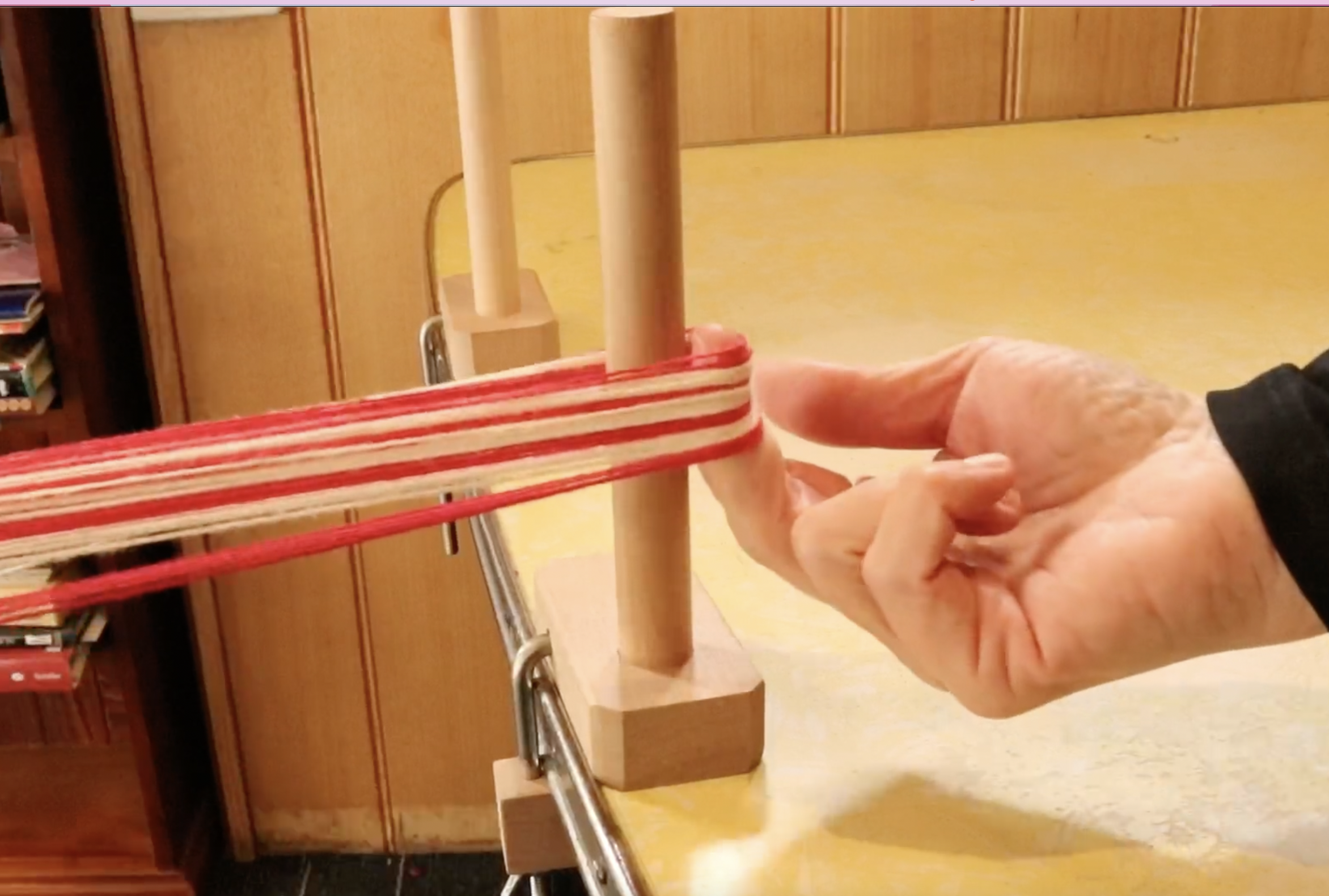

- Overloaded peg – If your entire warp is on one peg, the peg can get overloaded. This does depend on the width of your warp (number of warp threads) and the thickness of your yarn.

If you don’t want to purchase an additional peg, there are other options. Coat racks can be a perfect solution, and some weavers prefer to use more than 2 pegs, which also works great. If you opt for a coat rack, just ensure that it has straight, smooth pegs, like this one does – otherwise it could be hard to remove your warp from it.

Tip 2 : Be gentle!

This stage of the warping process is not the time to tensioning your warp, ready for weaving. Yes, you want to maintain a consistent tension whilst warping, so that your threads stay fairly even and everything is nice and neat, but the proper warp tensioning will occur in the winding on of the warp.

Winding your warp around the peg/s too tightly can actually be detrimental to the process. This is because the pegs are holding a lot of tension. If the tension increases too much, that carefully clamped peg can come loose, and if you have any experience with this, you know what happens next! 😆

The peg can come loose with a “ping” and make spaghetti out of your carefully wound warp in a second flat!

Even if your peg manages to stay in place with your warp threads too tightly wound around it, once you are ready to take the warp off to start threading, you may find it difficult to remove from the peg.

Ideally, you should be able to get a couple of fingers inside the warp at all times, this ensures that you’re not winding too tightly around the peg.

An easy way to ensure that you’re warping around the peg with a loose enough tension is to have your yarn feeding off the cone or ball adequately. A cone/warping stand is ideal for cones of yarn, as it allows the yarn to wind off freely.

I also like to use 2 fingers inserted into the loop after pulling it through the slot with the reed hook. Then I simply walk towards the peg, keeping my fingers in the same place. I don’t pull on the warp, but just walk with it, then drop the loop gently over the peg.

I hope these tips make a difference to your warping experience! If you would like to see this post in video format, please view that here-

Until next time…

Happy Weaving!