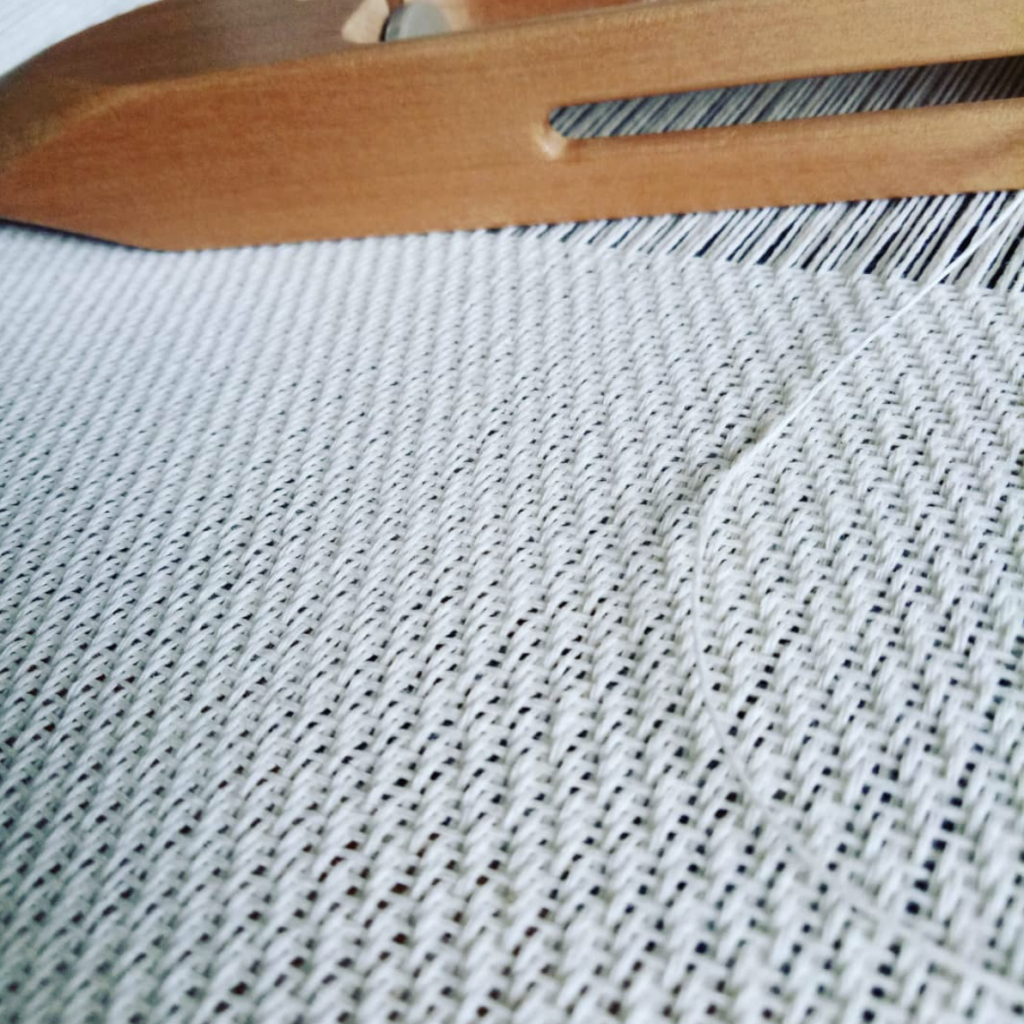

Welcome to the colourful and exciting world of floor loom weaving!

If you’re looking for a creative and relaxing hobby, weaving might just be your new favourite pastime. Don’t worry if you’re a complete beginner— with a good dose of patience, enthusiasm and just a bit of guidance, you can create beautiful projects in no time. Let’s dive into five fun weaving projects that will spark your creativity and boost your skills!

1. Simple Placemats

Kick off your weaving journey with some simple placemats! They’re quick to make and add a personal touch to your dining table.

- Materials Needed: Cotton yarn in various colors.

- Steps:

- Set up your loom with plain weave threading.

- Weave by alternating shafts 1 and 2 for plain weave.

- Finish the edges by tying simple knots or using a hem stitch.

- Tip: Don’t hesitate to mix and match colors—this is a great opportunity to experiment!

2. Basic Scarf or Cowl

Next up is a lovely scarf! It’s perfect for keeping warm or levelling up your wardrobe and makes a wonderful gift for friends or family.

- Materials Needed: You have so many choices here! Some options (click to see examples) would be:

- Wool

- Tencel

- Bamboo

- Acrylic

- Cotton

- Steps:

- Warp the loom according to the desired scarf width and length (don’t forget to pre-calculate. The Introduction to Floor Loom Weaving course includes printable calculation sheets).

- Explore basic patterns like plain weave or twill.

- Hemstitching on the loom is a great way to secure your ends, then a twisted fringe adds a really stylish and professional looking finish.

- Encouragement: This project is not only practical but also a great way to showcase your personality through color and patterning choices!

The project for my Introduction to Floor Loom Weaving online course is a beautiful cowl which is perfect for beginner floor loom weavers and beyond.

3. Woven Wall Hanging

Transform your space with a beautiful woven wall hanging. This project allows for creativity and self-expression. Pretty much anything goes – if you like it then it’s good!

- Materials Needed: A mix of fibres is possible here, and a dowel for hanging. This can be a terrific project for using up stash yarn.

- Steps:

- Set up your loom for free-form weaving. Plain weave threading is perfect.

- Experiment with different techniques like looped or knotting. You could weave a balanced plain weave or a weft faced weave (more like tapestry).

- Finish by attaching it to a dowel.

- Tip: Choose colors that resonate with you and your decor for a piece that feels uniquely yours!

4. Tote Bag

A practical project, a woven tote bag is perfect for carrying your essentials in style.

- Materials Needed: Sturdy yarn. You can use pre made handles or make your own.

- Steps:

- Weave a large rectangle in plain weave.

- Sew the sides together and attach the handles.

- If you want to get a little fancier, you can line the bag with commercial fabric like I do in the Tote Bag Series.

- Encouragement: It’s not just useful; it’s a great way to show off your weaving skills wherever you go! I love projects that are both practical and useful 😉

5. Baby Blanket

For a larger project that’s oh-so-rewarding, consider weaving a baby blanket. I recommend completing a baby blanket before trying a larger sized throw or blanket because it gives you all the practice you will need. Seeing a fresh little human being wrapped up in a handwoven blanket made with love just warms my heart.

- Materials Needed: Cottons are safest for babies.

- Steps:

- Warp your loom to accommodate the blanket size.

- Explore with your weave structure if you’re ready, but be careful there are no long floats where little fingers and toes could catch. Plain weave is lovely for blankets too. Check out Tom Kinsley’s Handwoven Baby Blankets book for heaps of inspiration and blankets to try!

- Finish by securing the edges. Neatly finished double fold hems are best for babes.

- Tip: This blanket can become a treasured item for years to come — babies who grow into children who grow into adults can get quite attached to their blankies!

- BONUS TIP

There are so many great weaving books available but I recommend that you start out with a draft and pattern directory like Anne Dixon’s Handweaver’s Pattern Directory (4 shaft patterns) or Carol Strickler’s A Weavers Book of 8 Shaft Patterns.

These are the kind of books that I refer back to again and again or frequently flip through for inspiration.

Weaving on a floor loom is not only a fun craft but also a fulfilling creative outlet. It can even become a way to make an income doing something you love. Remember, every project you complete builds your skills and confidence, so don’t be afraid to experiment and make mistakes. Choose any project that excites you, (but be realistic – walk first, then run!) and let your creativity flow.

Until next time…

Happy weaving!

*This post may contain affiliate links. For more information, please see my disclosure policy.