Over the years, I’ve had so many women quietly tell me the same thing:

“My loom helped me through a really hard time.”

“Weaving is really helping me through this period of grief”.

“Weaving is good for my mental health”.

We don’t often talk about this side of weaving. We talk about the excitement of new projects, yarn choices, techniques and looms. But there’s another layer to it – the quiet support that weaving can offer when life feels heavy.

I want to explore that here – not as therapy advice, because I am definitely not a therapist! Not as a substitute for proper support, because that is absolutely key for healing of any kind.

But as an honest look at why weaving can feel deeply stabilising during stressful or painful seasons.

(And just to reiterate clearly – weaving is not a replacement for professional health care. If you’re struggling, please seek the right support!)

The Comfort of Repetition

Think about what happens at the loom.

Throw the shuttle.

Beat.

Change shed.

Repeat.

There’s something incredibly regulating and grounding about that gentle rhythm.

When life feels chaotic or uncertain, the loom does not change. The process is the same today as it was yesterday. The loom waits until we’re ready for the next weaving session.

Our nervous systems respond well to predictable, repetitive movement. Both hands working. A steady pace. Clear steps.

You don’t have to make a hundred decisions.

If you run into problems or errors you can address them quietly and in your own time.

Then you progress to the next step.

It’s just you, the weaver, and the loom in that moment of time.

That simplicity can be a relief.

Weaving During Stressful Seasons

There was a period in my life when my son was very ill in hospital for an extended time. It was exhausting and uncertain, and there were so many things completely outside my control. At times, we didn’t know if he would make it.

To add to the distress, I was quite sick with the flu myself and there were many days that I couldn’t be with him at the hospital, which was quite a distance from our home.

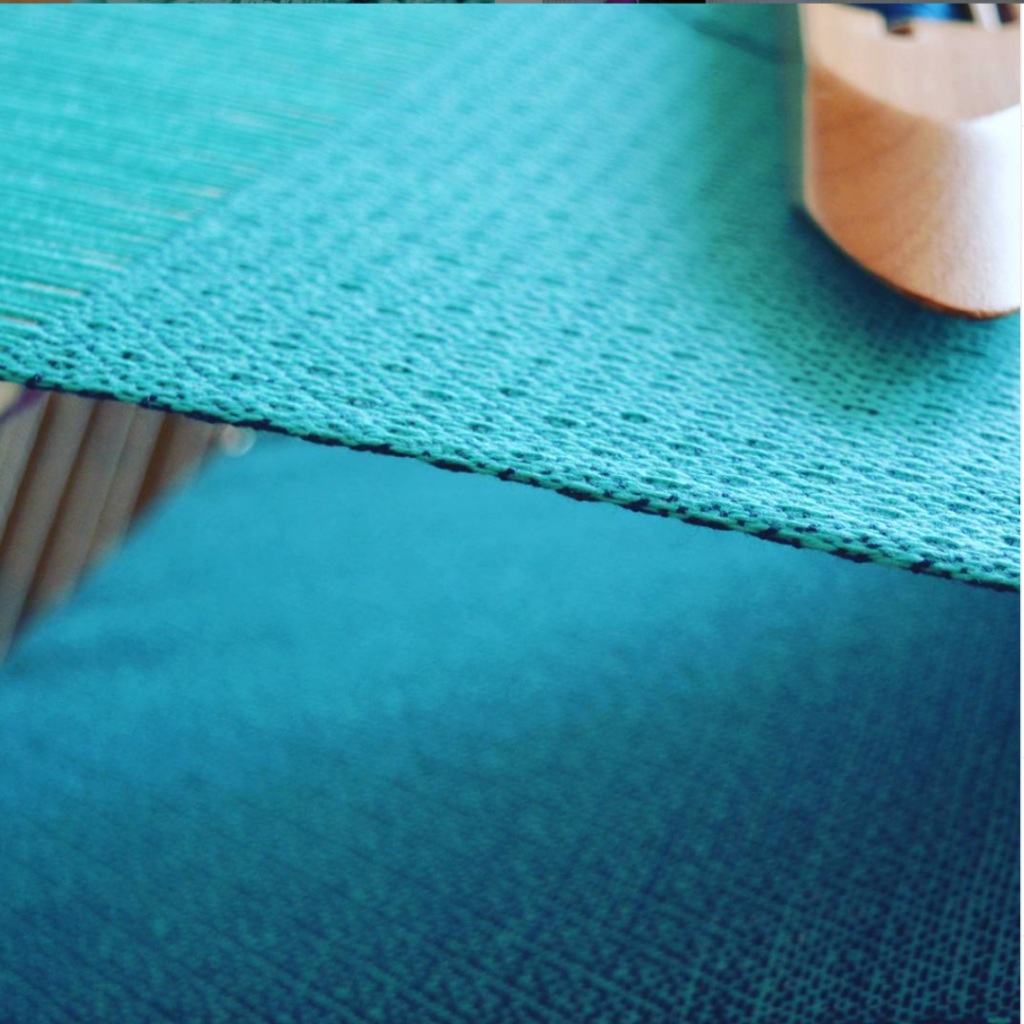

During that season, weaving became something steady.

It didn’t solve the situation or remove the stress. Actually, at first I felt selfish for sitting at the loom when I couldn’t be at my son’s side.

But it gave me:

- A familiar process

- A quiet mental focus

- A small sense of completion

When everything else felt unpredictable, the loom was predictable.

The warp was still straight.

The heddle still lifted and lowered.

Cloth still formed, one row at a time.

And sometimes, that was enough to steady me for the day. I even made a Youtube video during that time because it helped me to feel I was doing something positive for someone else.

Weaving and Chronic Illness

If you live with chronic illness, you’ll understand how much it can affect your sense of identity and capability.

Energy shifts.

Plans change.

Progress feels inconsistent.

One of the things I’ve appreciated about weaving is that it allows for slowness.

You can sit and weave for ten minutes or longer if you feel up to it.

You can stop without “failing.”

Even weaving a small section of cloth can restore a sense of competency and satisfaction – a reminder that your effort still produces something tangible.

Why Structure Feels Safe

Weaving is built on structure.

Warp first, then weft, tension balanced, order maintained. Step by predicable step.

There is real comfort in that structure.

When your emotions feel messy or overwhelming, when your thoughts lack clarity, working within a clear system can feel grounding. You are not staring at a blank canvas wondering what to do. You follow steps, repeat sequences and see progress.

Rigid heddle weaving in particular lends itself beautifully to this. Once your loom is dressed, the work becomes rhythmic and contained. The setup takes less time so is more manageable.

Weaving Through Grief

Grief is difficult to put into words and can be so individual.

Textile work gives your hands something to do when your mind feels foggy. It’s something tangible and stable in a time where nothing feels controllable. Weaving can feel like “something to hold on to”.

Some women choose to:

- Weave with colours that remind them of someone

- Create a small memorial piece

- Weave for someone else who is grieving or going through a difficult stage

- Incorporate meaningful yarn into a project

Creating a Gentle “Healing Weaving” Practice

If you’re walking through a stressful season and would like to use your weaving as support, here are a few simple ideas:

Keep one loom dressed.

Remove the barrier of setup.

Choose simplicity.

Plain weave. Soft colours. No pressure to be clever.

Weave how you feel.

Ten minutes is enough if that is all you can cope with. Or spend the entire day at the loom if you are able. Whatever feels most healing for you for today.

Let it be private.

Not everything needs to be shared online or with others if you don’t want to. Just like artwork, it can be done just for you.

Notice the rhythm.

The sound of the shuttle.

The beat of the reed.

The growing cloth.

Sometimes the most helpful thing is simply the repetition.

What Weaving Is and Isn’t

Weaving is not a cure for everything.

It’s not therapy and it’s not a fix for trauma.

But it can be:

- A steady rhythm

- A quiet anchor

- A creative outlet

- A small place of control in a season that feels out of control

Across history, women have woven through war, loss, uncertainty and transition. Cloth has always been made during ordinary days and very hard ones.

There is something deeply human about building structure when life feels unstructured.

If you’ve experienced weaving as something more than just a hobby, I would love to hear about it in the comments.

You may be encouraging someone else more than you realise.

If you are in a season of struggle and don’t feel you’re coping, I urge you to please, get help. Whether it’s talking to friend, family member or someone you trust online. Maybe it’s joining a support group. Or maybe you need to go deeper and seek out professional help. You don’t have to do it all alone ❤️

Until next time…

Happy Weaving!