Winter has a funny way of slowing us down – shorter days, cooler weather, and a natural pull toward cosy, comforting activities. For many of us, that makes it the perfect season for weaving.

If you’re looking for inspiration, winter is a wonderful time to focus on rigid heddle weaving projects that are warm, practical, and satisfying to make. The kind of projects that feel good on the loom and get plenty of use once they’re finished.

Personally, I am a practical person and so I have a great desire for my weaving projects to be very purposeful.

In this post, I’m sharing some of the best winter rigid heddle weaving projects, whether you’re a beginner or a more experienced weaver looking for something cosy and rewarding to work on.

Why Winter Is Perfect for Rigid Heddle Weaving

Winter weaving just hits differently. As soon as Autumn starts to roll in, something stirs within me and my creative mind goes into hyperdrive! By the time Winter arrives, I usually have a list of “must weaves”.

It’s a season that naturally suits:

- Slower, more mindful making

- A desire or need to be warm and work with fibres like wool that just feel good in this season

- Projects you can work on in small or longer pockets of time

- Textiles that are meant to be physically used, not just admired

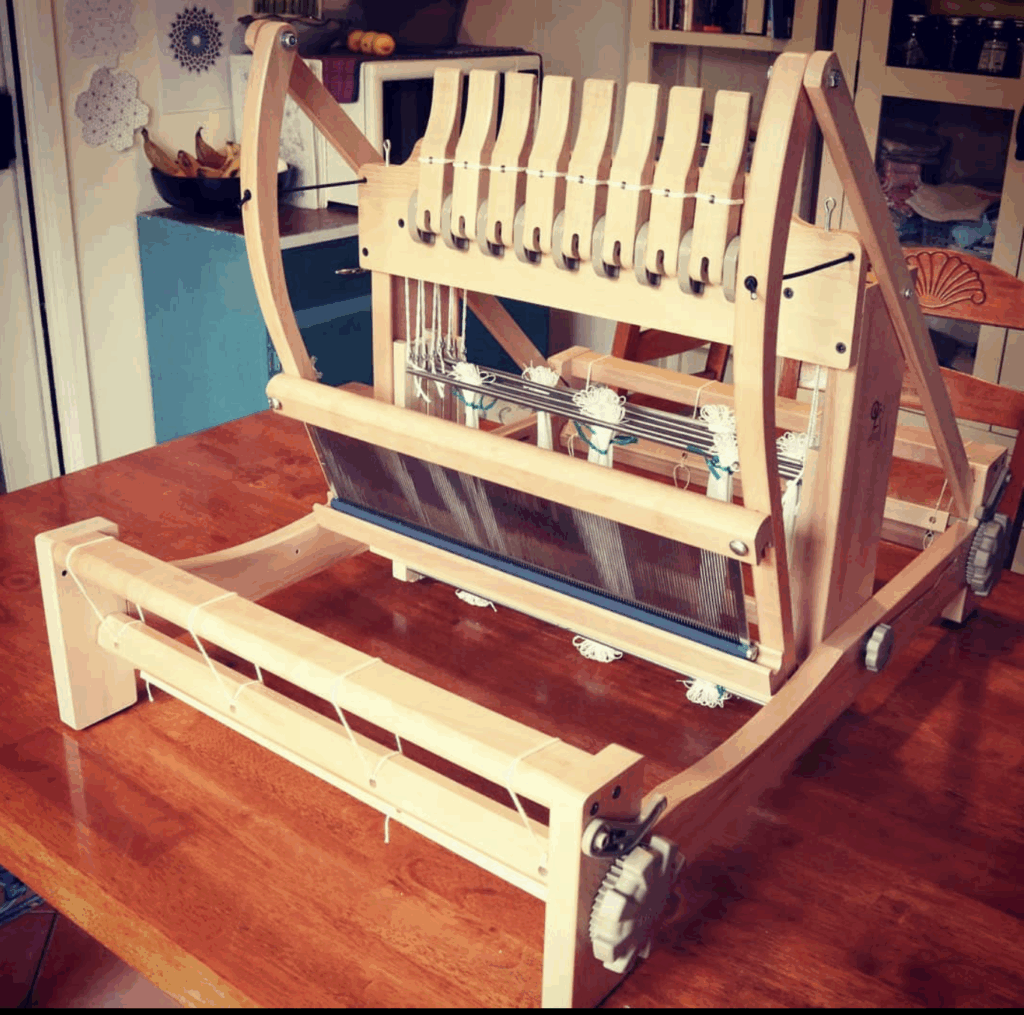

Rigid heddle looms are especially well suited to winter projects because they’re:

- Quick to dress compared to floor looms

- Ideal for cosy, textured fabrics

- Easy to leave warped and come back to without fuss

- Great for thicker yarns like knitting wool

If your energy and mood dips a little in winter (you’re not alone), choosing the right project makes all the difference.

Scarves: A Winter Weaving Classic (for Good Reason)

Scarves are a go-to winter project, and honestly, they deserve their popularity.

They’re:

- A manageable size for a weaving project, making them a great beginner weaver option

- Easy to customise

- Great for experimenting without overwhelm

- Literally one of the warmest things you can wear! I find that if my neck is warm it really helps the rest of me to feel warm

On a rigid heddle loom, scarves are perfect for playing with:

- Thicker yarns like wool or wool blends

- Texture (waffle weave, other pick up patterns, or simple colour changes)

- You choose the width and length according to personal preference

If you’re newer to weaving, a scarf is an excellent confidence builder. If you’re more experienced, it’s a lovely way to try a new technique without committing to a huge project. If you don’t intend to keep the scarf for yourself (let’s face it, we can’t keep every one!) they may wonderful gifts.

Resources for Scarf Weaving

Rigid Heddle Beginner Scarf Bundle…

The Heart Scarf (Free Project)…

Join My Mailing List to Receive the Free Moroccan Dreams Scarf Pattern…

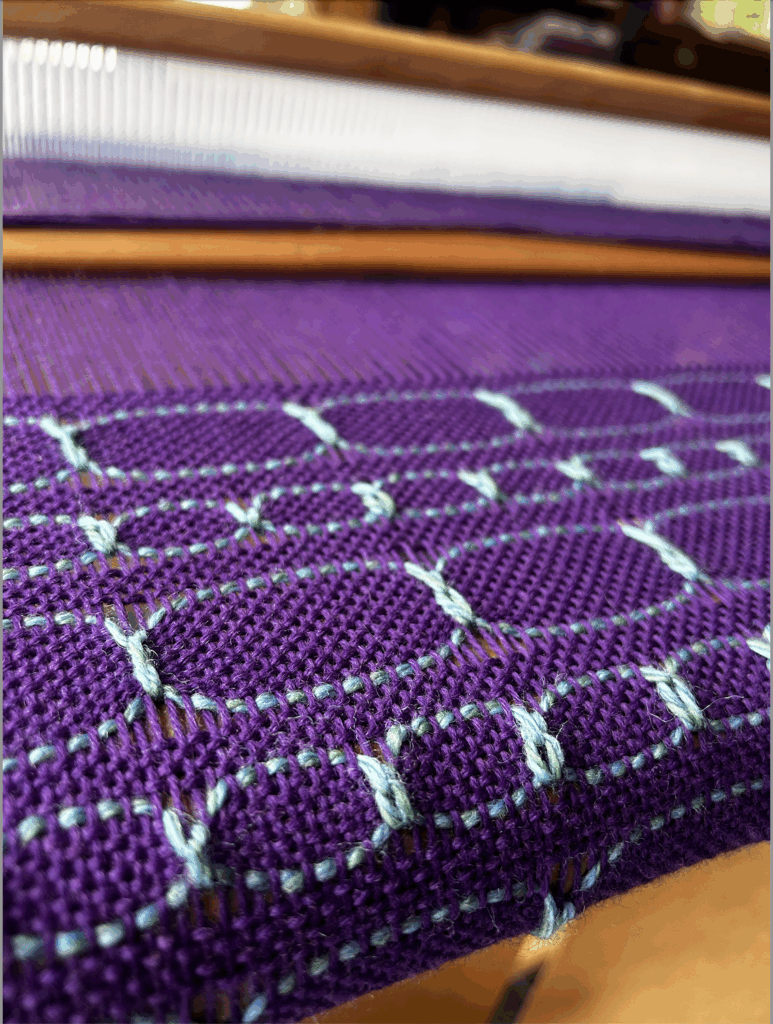

Shawls and Wraps for Cosy Layering

Winter is also a beautiful time to weave shawls and wraps, especially if you enjoy slightly longer projects that still feel achievable.

Rigid heddle looms are great for:

- Rectangular wraps

- Narrower shawls sewn together from panels

- Lightweight but warm fabrics using wool or alpaca

Shawls are particularly satisfying because they:

- Feel a little more “special” than a scarf but are basically an upsized scarf!

- Work well with simple or more complex weave structures

- Are wonderful gifts (or well-earned keepsakes)

- Provide many options for exploring colour, pick up techniques or finger controlled techniques

If you tend to weave in the evenings, shawls are a lovely project to have on the loom – steady, rhythmic, and very calming.

Resources for Shawl Weaving

The Mobius Shawl (Free Project)…

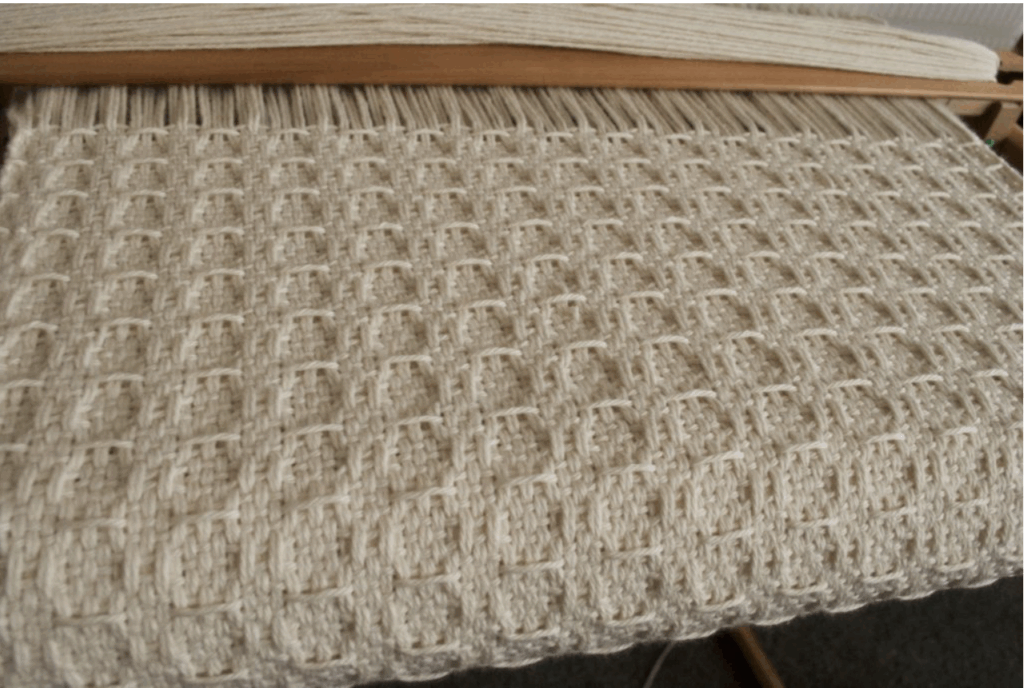

Blankets and Throws (Yes, You Can on a Rigid Heddle Loom)

Winter is when many weavers start dreaming about blankets (sometimes I think that blankets are a bit of an obsessions for me 🤭) and while large blankets can feel intimidating, rigid heddle looms handle them surprisingly well.

Some winter friendly options include:

- Baby blankets

- Lap blankets

- Throws made from multiple woven panels

- Even full sized bed blankets

Blanket weaving is well suited to rigid heddle looms because:

- You can weave narrower panels to seam together off the loom if loom size is an issue

- Thicker yarns work well and are extra cosy

- The end result is incredibly satisfying

- Double width weaving is a great way to weave a larger blanket

Winter is also a great time for these projects because you’re not in a rush. You can let them unfold slowly and consistently.

Resources for Blanket Weaving

Cushions and Homewares for Winter Comfort

If wearables aren’t your thing, winter is a wonderful season to weave homewares. Textiles have been used for a very long time to increase warmth, omit drafts and provide happy colours to homes.

Think:

- Cushion covers

- Table runners

- Wall hangings with a warmer, textural feel

These projects are ideal if you:

- Want something that will make a difference to your living space/s

- Enjoy playing with texture or colour

- Like seeing your weaving used every day

Thicker yarns, weft faced weaving, and simple patterns really shine here, and rigid heddle looms are perfect for creating sturdy, practical fabrics that hold up well to use.

Resources for Cushions and Homewares

Cowls and Neck Warmers: Small but Mighty Projects

If winter energy is low, and your need to feel warm and cosy is high, cowls and neck warmers are a fantastic choice.

They’re:

- Quick to weave

- Easy to finish

- Are very yarn friendly

- Very wearable

A short warp, a cosy yarn, and a simple weave structure can still produce something beautiful and are very welcome on cold mornings.

These are also excellent projects if you:

- Want fast finishes

- Are weaving for gifts

- Need to warm up fast!

- Need a “palette cleanser” between larger projects

Resources for Neck Warmer and Cowls

Tips for Choosing the Right Winter Weaving Project

When deciding what to weave in winter, it helps to ask yourself a few simple questions:

- Do I want something quick or something slow and steady?

- Do I want to learn, or just enjoy the process?

- Will I actually use this when it’s finished?

- Do I need a low yarn project or is a bit more yarn ok?

Winter Is for Cosy, Enjoyable Weaving

Winter is a time for hot tea, warmth, comfort, and making things that feel good to create in the season.

The right project can turn winter weaving into something you genuinely look forward to – hot drink nearby, loom waiting patiently, no pressure at all.

If you’ve been wondering what to weave this winter, I hope this list has sparked a few ideas and reminded you that simple, cosy rigid heddle weaving projects are a great way to keep you warm and happy!

Until next time…

Happy Weaving!

*This post contains affiliate links. For further information please see my disclosure policy.