I have quite a few free video tutorials to get those creative juices flowing:

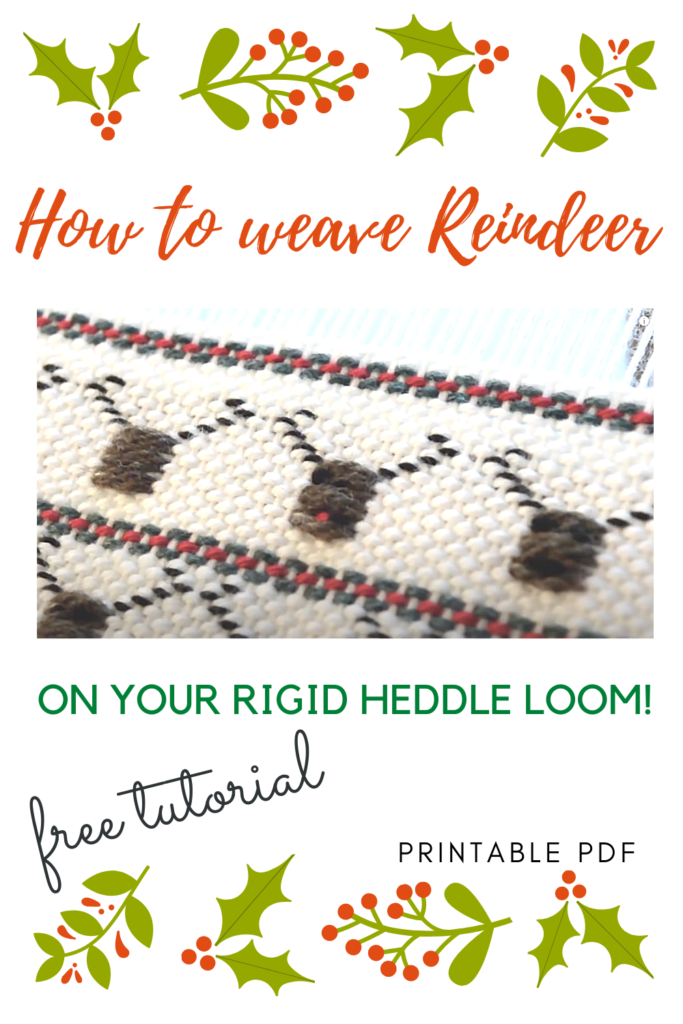

Reindeer on a rigid heddle loom

Handwoven No Sew Christmas Hearts

Gift boxes on a rigid heddle loom

Winter Trees

Snowmen on a rigid heddle loom

I hope these inspire you to add some beautiful hand woven

Christmas cheer to your home or someone else’s!

Until next time…

Happy Weaving!

🎄 🎄🎄🎄🎄🎄