Pros, Cons & Practical Things to Consider

It’s a question I hear all the time:

“Should I buy a larger rigid heddle loom… which size is best for me?”

Bigger looms are very tempting. The idea of weaving wider fabric, growing into your skills, and not having to upgrade again later can be appealing – but a larger loom isn’t automatically the right choice for everyone.

Before you invest, it’s worth slowing down and thinking through some very practical considerations. In this post, I’ll walk you through the pros, cons, and key questions to help you decide whether a larger rigid heddle loom is right for you.

Practical Considerations Before Buying a Larger Loom

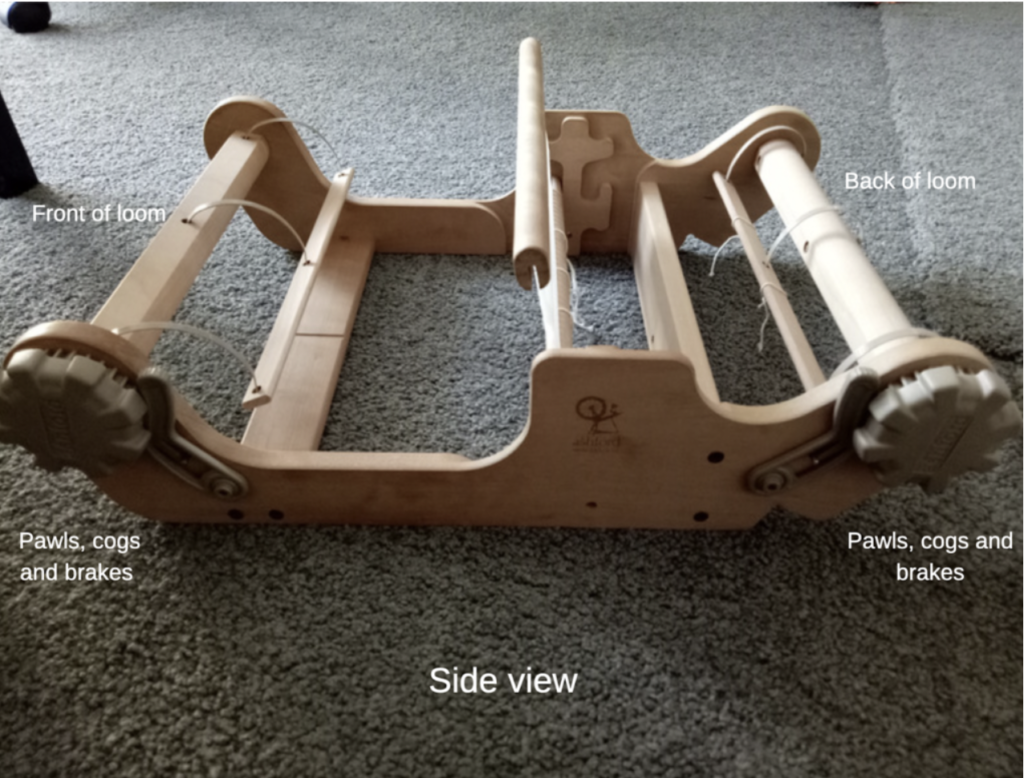

Do You Have the Physical Space?

This is the first (and sometimes overlooked) question.

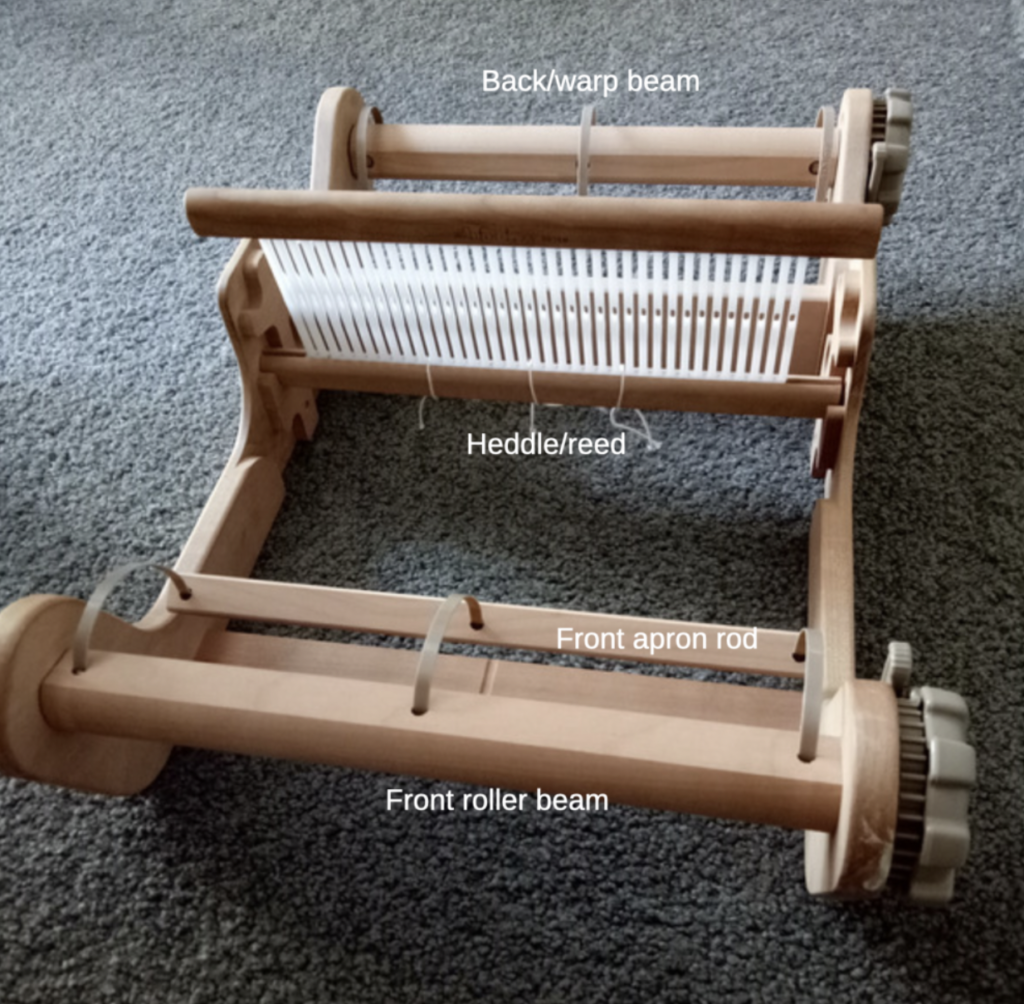

A larger rigid heddle loom:

- Takes up more floor or table space

- Needs room in front of you for comfortable weaving

- Needs somewhere safe to store it when not in use (if you don’t have a space to leave it in)

If you’re tight on space, a 32″ or 48″ loom can feel quite large and may be overwhelming – not just physically, but mentally too.

What Is Your Budget?

As looms get wider, everything gets more expensive – not just the loom itself, but also the parts. Here are some pricing examples of larger Ashford Rigid Heddle Looms and Ashford Rigid Heddles. These prices in USD were pulled from the Woolery.

Loom price examples (USD / AUD approx.)

- 24” Ashford rigid heddle loom – ~$345

- 32” loom – ~$379

- 48” loom – ~$639 USD / ~$965 AUD

Heddle price examples

- 24” heddle – ~$51

- 32” heddle – ~$62.50

- 48” heddle – ~$133 USD / ~$200 AUD

Those costs add up quickly, especially if you want multiple heddles for different yarn weights.

What Do You Intend to Weave?

Think realistically about what you actually want to weave. If you’re brand new to weaving, It can be difficult to know, but most of us start out with some desired projects in mind.

- Scarves, cowls, and table runners don’t require a very wide loom

- Shawls, blankets, yardage, and garments will benefit from extra width

- Some projects can be woven narrower and joined later

Do You Have Any Physical Limitations?

Be real with yourself. It’s no good making a large investment in a loom that you can’t use.

A wider loom means:

- Reaching further to pass the shuttle

- Handling a wider and heavier heddle

- Potential strain on shoulders, neck, back and wrists

Some weavers find that even a 32″ loom causes discomfort, especially during longer weaving sessions. Others have no problems with a wider width at all. This is a very personal factor and an important one to be honest about.

Pros of Buying a Larger Rigid Heddle Loom

The Loom Can Grow With You

One of the biggest advantages is flexibility.

You can:

- Start by weaving narrower projects

- Gradually work up to wider pieces as your skills and confidence grow

You’re not forced to weave wide just because the loom allows it.

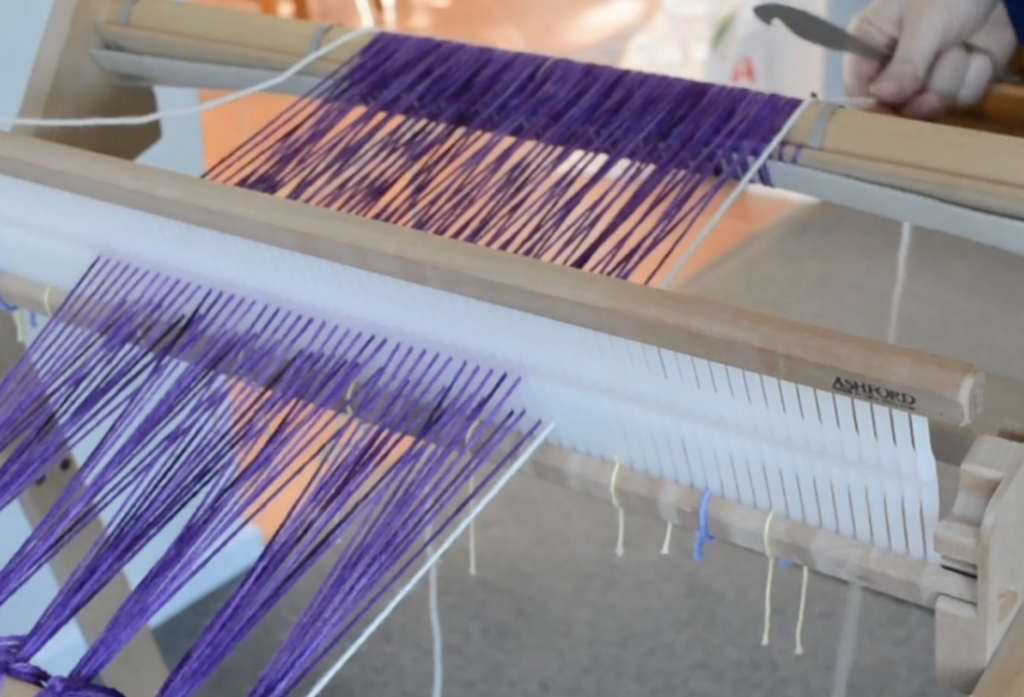

You Can Weave Wider Fabric

This is the obvious benefit — and for some weavers, it’s a game changer.

A larger loom allows you to:

- Weave wider shawls and wraps

- Create fabric for garments

- Experiment with yardage and homewares

If wide fabric is central to your weaving goals, this may tip the balance in favour of a larger loom.

Great Resale Value

Larger rigid heddle looms tend to hold their value well.

Many weavers:

- Start small

- Look to upgrade later

- Actively seek out larger looms second-hand

So if you do decide to sell later, there’s often good demand.

Cons of Buying a Larger Rigid Heddle Loom

Increased Physical Strain

For some weavers, wider looms mean:

- Shoulder fatigue

- Difficulty reaching across the warp

- Struggling with a wide heddle

Comfort matters. If weaving becomes uncomfortable, it stops being enjoyable.

Higher Cost Overall

As mentioned earlier, the loom itself costs more, but so do:

- Extra heddles

- Accessories

- Replacement parts

Takes Up More Space

A larger loom:

- Needs more room to use comfortably

- Is harder to tuck away between projects

- Can dominate a small weaving area

Less Portable

If you like to:

- Weave in different rooms

- Take your loom to workshops or groups

- Pack it away frequently

A larger loom is simply less convenient to move.

Warping Takes More Time and Care

Wider warps mean:

- More opportunities for uneven tension

- More patience required

- More care during setup

This isn’t a deal-breaker, but it’s something beginners often underestimate.

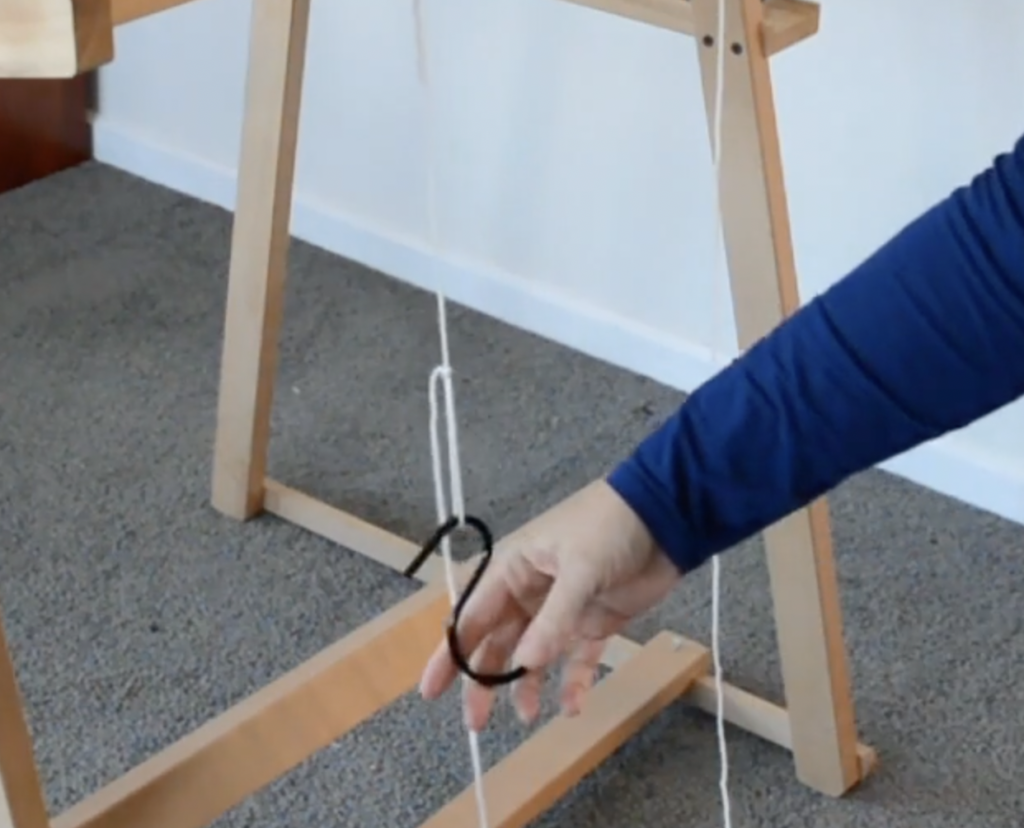

My Recommendations

Absolute Beginners

If you’re brand new to weaving:

- Start with a smaller loom. Personally, I think a size like my 24″ Ashford is perfect. Small enough to not cause physical issues and large enough to weave towels, shawls, runners and even blankets (double width weaving).

- Save the extra to grab a stand for your loom. You will thank me later 😉

- Learn the basics

- Upgrade later if you feel limited

There’s no rush.

Think About Ergonomics

If you do go larger:

- Use a height-adjustable chair to get close to your loom on a stand

- Wheels on a chair can make repositioning easier

- Pay attention to posture and comfort

- Lumbar support is super helpful! I love my old office chair, I haven’t found another quite like it, but at a basic level you’re looking at something like this.

Your body will thank you.

Don’t Forget Double Weave

Before buying wider, remember:

- Double width weaving allows you to create wider fabric on a narrower loom

It’s a powerful technique and well worth learning before assuming you need more width. The only drawback is that you’re limited to plain weave on a rigid heddle loom for double width due to the number of shafts required.

Final Thoughts

A larger rigid heddle loom can be a wonderful tool, but it’s not automatically better.

The right loom is the one that:

- Fits your space

- Fits your body

- Fits your budget

- Fits what you actually want to weave

Take your time, be realistic, and choose the loom that will help you enjoy weaving for years to come.

If you’re interested in seeing me discuss these, and more aspects around buying a larger rigid heddle loom, check out this free video ⬇️

*This post contains affiliate links. For more information, please see my disclosure policy.

Until next time…

Happy Weaving!