I find that towels are one of the most satisfying things to weave. They are practical, gift-worthy, and so customisable. If you’ve ever wondered how to weave towels that are absorbent, durable and enjoyable to use, this guide will walk you through what you need to know.

Not all towels are created equal. A kitchen towel has different demands to a hand towel, and a bath towel is a whole other level again.

In this article, I’ll walk you through the three main types of towels you can weave – kitchen towels, hand towels and bath towels. We will talk about:

- suitable yarns for each

- suitable loom types

- weave structure considerations

- and links to patterns and resources if you want a proven starting point

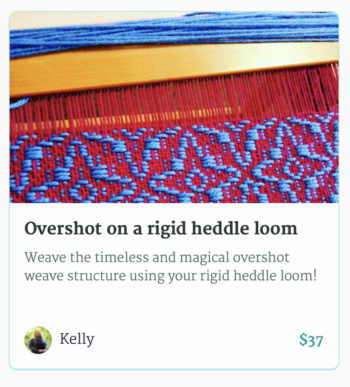

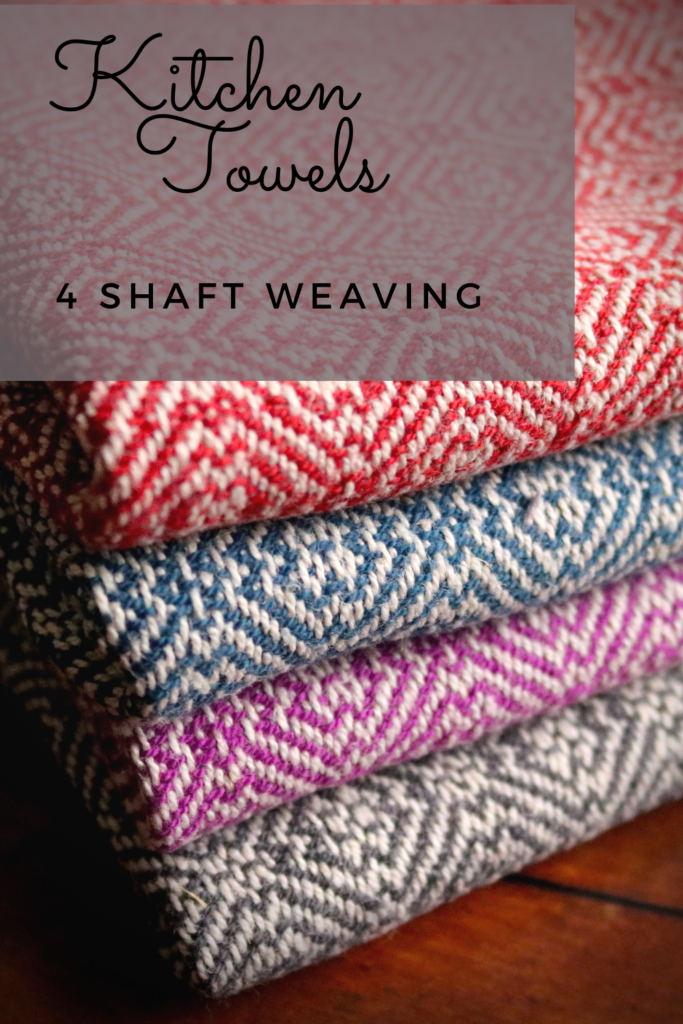

1. Kitchen Towels (Tea Towels)

Kitchen towels (we call them tea towels in Australia!) are usually the first towels handweavers make, and they’re an excellent place to start if you’re learning how to weave towels.

Kitchen towels are such a great place to start. They’re quick to weave, highly practical, and a fantastic way to experiment with colour, structure and yarns.

What a kitchen towel needs to do:

- Be highly absorbent

- Dry quickly

- Stand up to frequent washing

- Feel pleasant but not fluffy

Best yarns for kitchen towels (absorbent & durable)

- Cotton (8/2 or 10/2 is ideal)

- Cotton-linen blends (I love 8/2 cottolin for kitchen towels)

- Linen (beautiful, but better for experienced weavers)

Avoid wool or acrylic – they simply don’t absorb well enough. They will repel, rather than absorb moisture.

I have a more detailed article about which cotton to use for kitchen towels here.

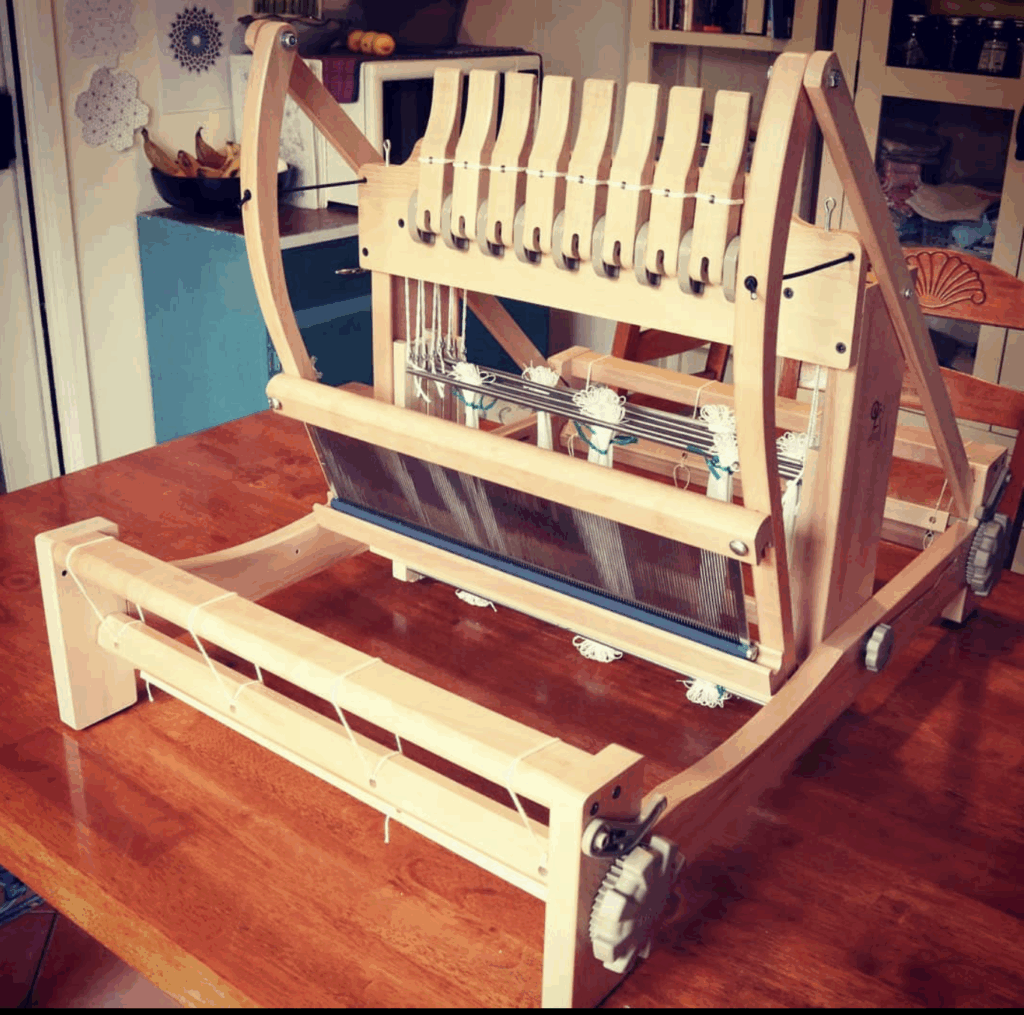

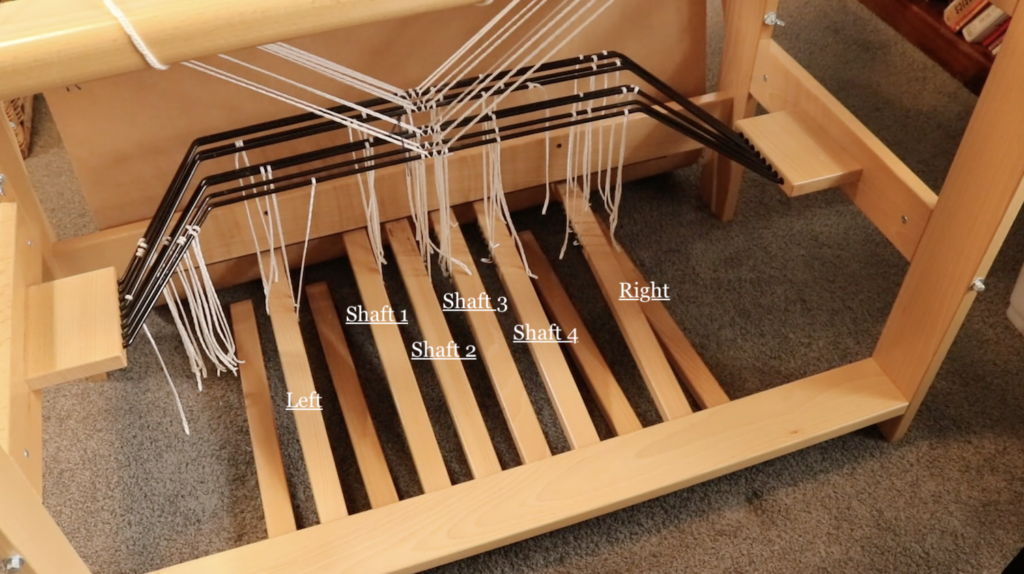

Best looms for weaving kitchen towels

- Rigid heddle looms (perfect for beginners)

- Table looms

- Floor looms

Kitchen towels are very forgiving and work beautifully on a variety of looms.

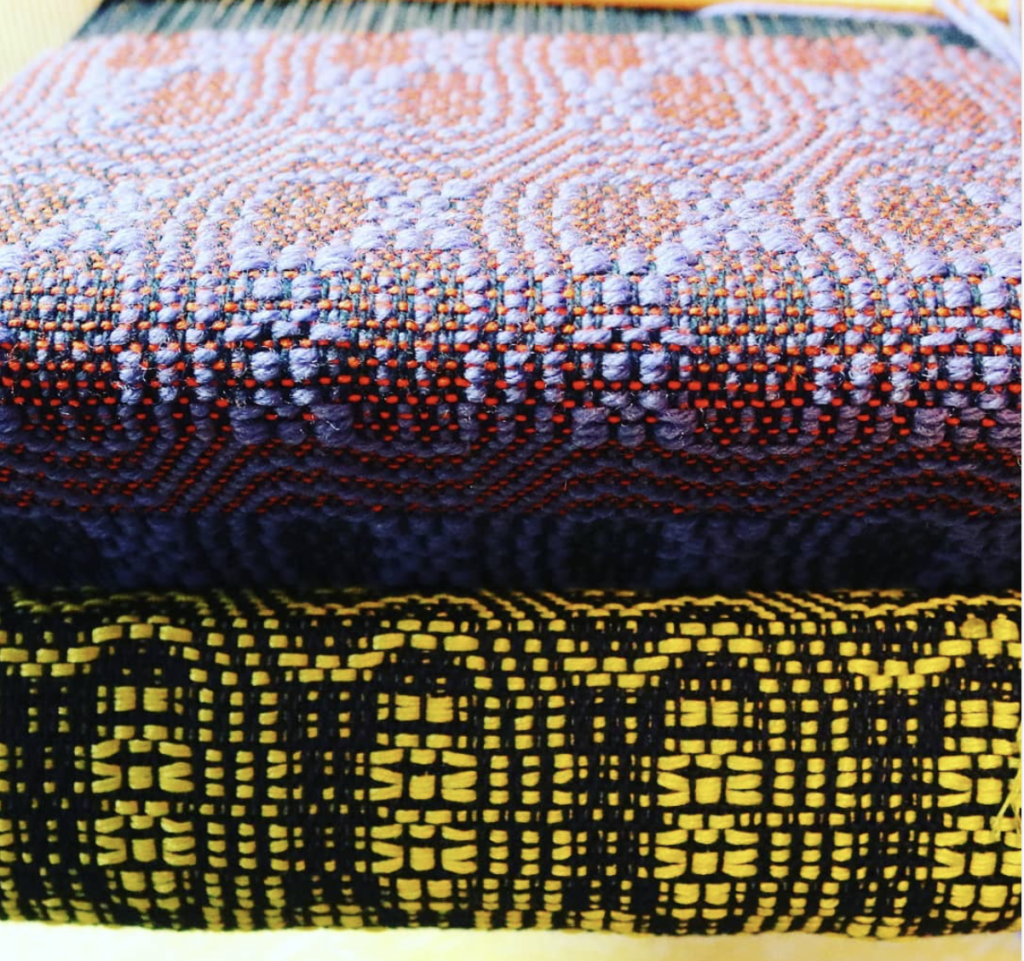

Best weave structures for kitchen towels

- Plain weave (simple and effective)

- Waffle weave (especially absorbent)

- Simple twills

- A combination of structures for a beautiful, classic look like these

- Summer and Winter actually makes beautiful towels

2. Hand Towels

Hand towels bridge the gap between kitchen towels and bath towels. They need to be practical, but they’re also something you see and touch every day in the bathroom or kitchen.

Hand towels sit somewhere between kitchen towels and bath towels – they need to be absorbent, but also soft and attractive. They are usually thicker in weight and larger in size than a kitchen towel.

What a hand towel needs to do

- Absorb water efficiently

- Feel good against the skin

- Look nice hanging in a bathroom or kitchen

Best yarns for weaving hand towels

- 8/4 cotton (will weave a thicker fabric than 8/2 cotton)

- Cottolin (cotton/linen blend – once again a heavier weight is preferable)

- Knitting cotton

- Cotton blends (choose natural fibres)

You can afford to prioritise softness and loftiness here more than with kitchen towels.

Best looms for weaving hand towels

- Rigid heddle looms (with slightly wider widths)

- Table looms

- Floor looms

If weaving on a rigid heddle loom, consider using pick up sticks or two heddles to allow for more interesting structures.

Best weave structures for hand towels

- Twills

- Waffle weave

- Honeycomb

- Subtle textured patterns

3. Bath Towels

Bath towels are the most advanced towel project for handweavers because they are a large size and may require a more significant time investment if using a technique like loop pile (keep reading if that piques your interest!)

Bath towels are the most ambitious towel project, but can be very rewarding.

What a bath towel needs to do

- Be very absorbent

- Feel soft against the skin

- Be strong enough for heavy use

- Have good drape

- Be regular wash friendly

Best yarns for weaving bath towels

- Fine cotton (8/2 or finer)

- Unmercerised cotton for maximum absorbency

- Cotton/bamboo blends for softness

- Other plant fibres can also be used successfully, like hemp, for example.

Bath towels usually require more yarn and more weaving time, so quality matters.

Best looms for weaving bath towels

- Floor looms (ideal)

- Large table looms

- Large rigid heddle looms

While bath towels can be woven on rigid heddle looms, width limitations often mean compromises or seaming. This won’t be an issue if your RH loom is 32″ or larger.

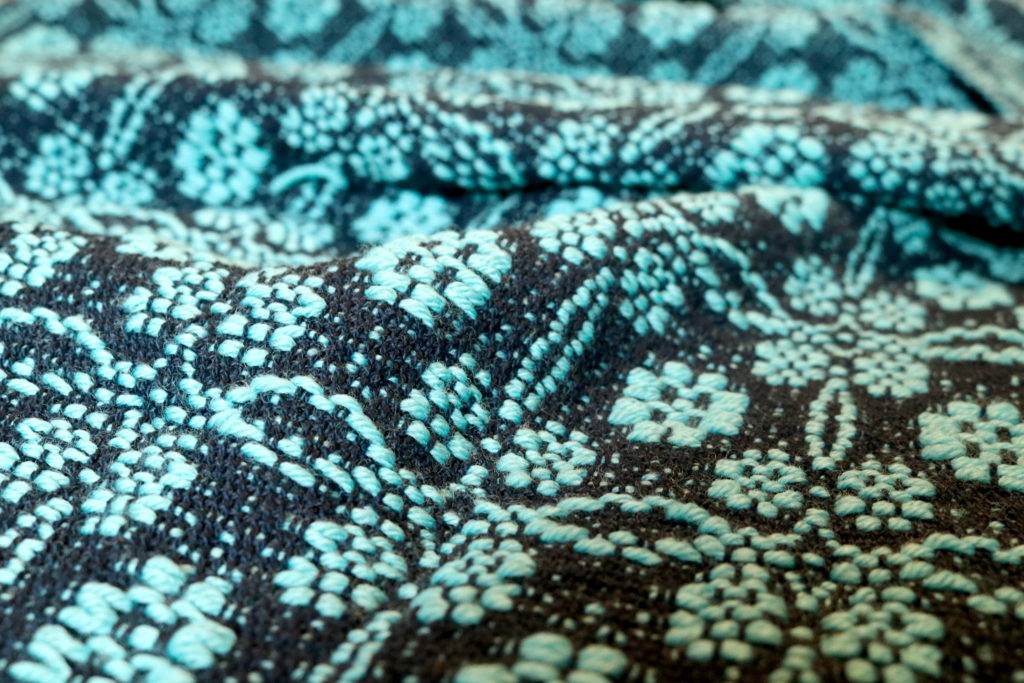

Best weave structures for bath towels

- Waffle weave (classic bath towel structure)

- Twill variations

- Textured blocks

- Loop pile or cut pile. Loop pile is the technique used for most commercially available towels. Cut loop is a little more luxurious and velvety but can be less absorbent. The loop pile technique is not hard to learn and is worked on a plain weave backing. My Lux Hand Towels pattern used loop pile as a decorative border.

Syne Mitchell has a handy section on loop pile in her book Inventive Weaving on a Little Loom, page 178- 181.

How to Choose the Right Towel Project for Your Loom and Skill Level

If you’re new to weaving towels, start with kitchen towels. Once you’re comfortable with yarn behaviour, finishing and shrinkage, move on to hand towels, and then tackle bath towels when you’re ready for a bigger commitment.

Each type teaches you something different, and all of them result in something genuinely useful.

Towel Weaving Resources (Kitchen, Hand & Bath)

If you’d like to learn more about weaving towels, I have a range of resources to help:

- Kitchen towel patterns →

Floor Loom 4 Shaft Class Towels

- Hand towel patterns →

Wash Your Hands Towels (free pattern)

These patterns remove the guesswork so you can focus on enjoying the weaving. Here are some other resources related to weaving towels:

- How to hem hand woven towels

- How to hem hand woven by hand (no sewing machine)

- Which cotton weight for kitchen towels

- Tips for weaving with cottolin

- New towels for our new home

Frequently Asked Questions About Weaving Towels

What is the best yarn for weaving towels?

For most towel projects, cotton yarn is the best choice due to its absorbency, durability and ease of care. I like 8/2 unmercerised cotton as it’s so easy to work with. Linen and cotton blends can also be used, particularly for kitchen and hand towels.

Can you weave towels on a rigid heddle loom?

Yes! Kitchen towels and hand towels are very well suited to rigid heddle looms. Bath towels are possible, but width limitations often make table or floor looms a better choice.

What weave structure is best for towels?

Waffle weave is one of the most popular structures for towels because of its excellent absorbency, but plain weave, twill and honeycomb can all work beautifully depending on the towel type.

Final tip: Always sample when in doubt. Towels change dramatically after washing, and sampling will tell you more than any chart ever could. This is especially important for weave structures like waffle weave, which has higher rates of shrinkage than plain weave.

I hope this guide has been super helpful to you 😊

Until next time…

Happy weaving!

*This post contains affiliate links. For more information, please see my disclosure policy here.