Choosing between a table loom and a floor loom is one of the biggest decisions a weaver can make. While both allow you to weave intricate multi-shaft weave structures, the way you achieve that – using hand-operated levers versus foot-operated treadles can completely change the weaving experience.

In my latest video, Levers vs. Treadles (Free Pattern Included!), I break down the physical differences, pros and cons, and the rhythm of each setup. I also use the free weaving draft included in this article (scroll to the bottom for your free copy 😉) and show you how I would approach the tie up for both levers and treadles.

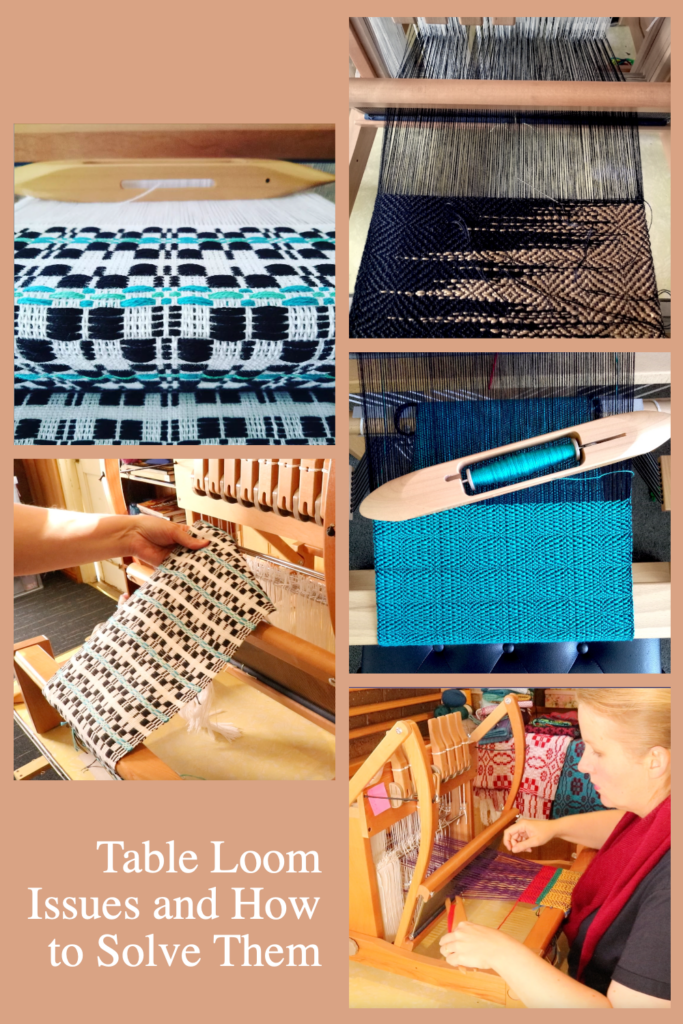

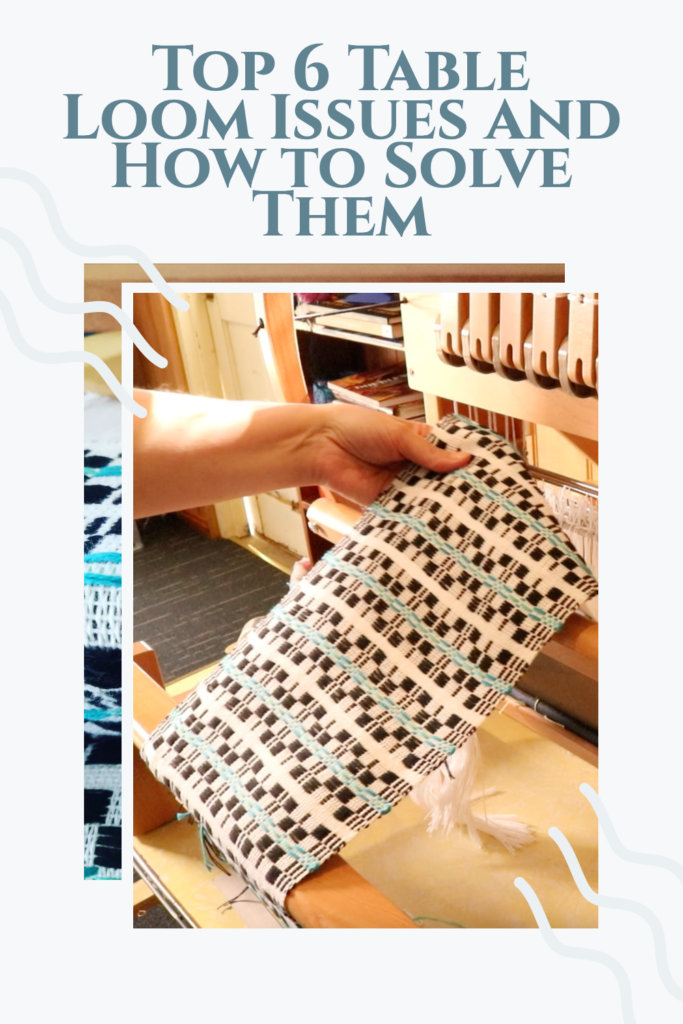

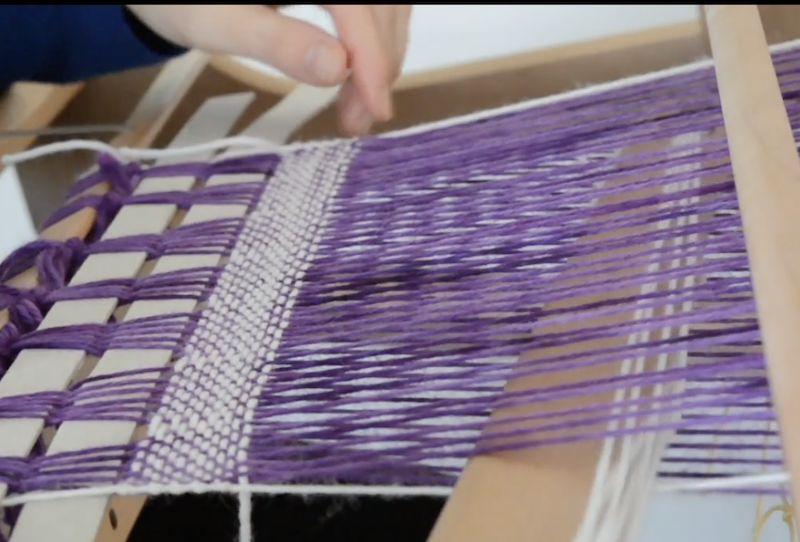

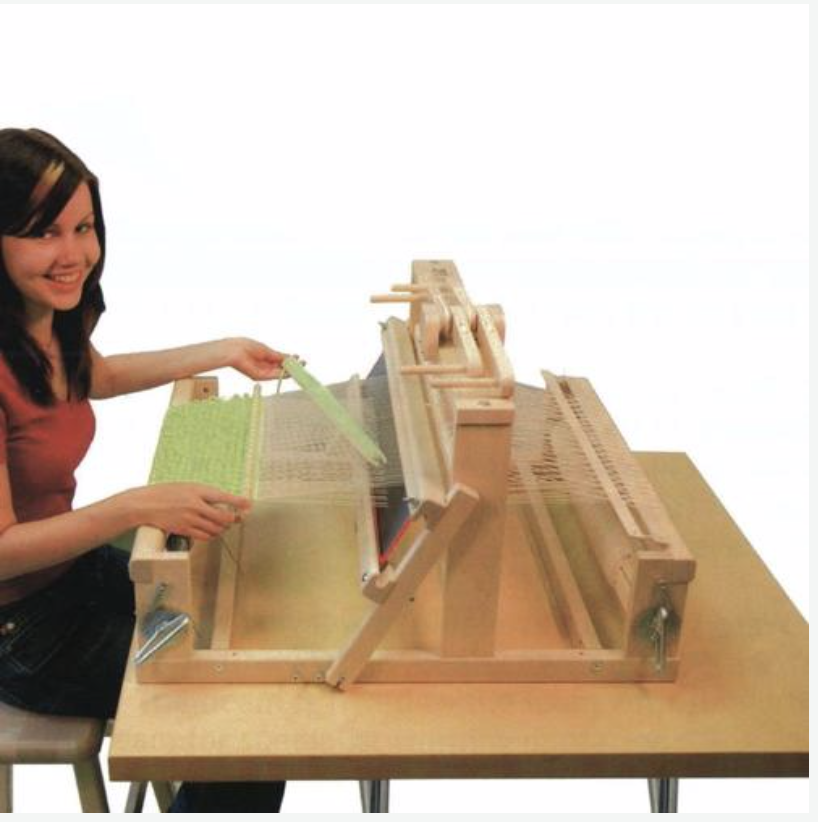

The Table Loom Experience: Weaving with Levers

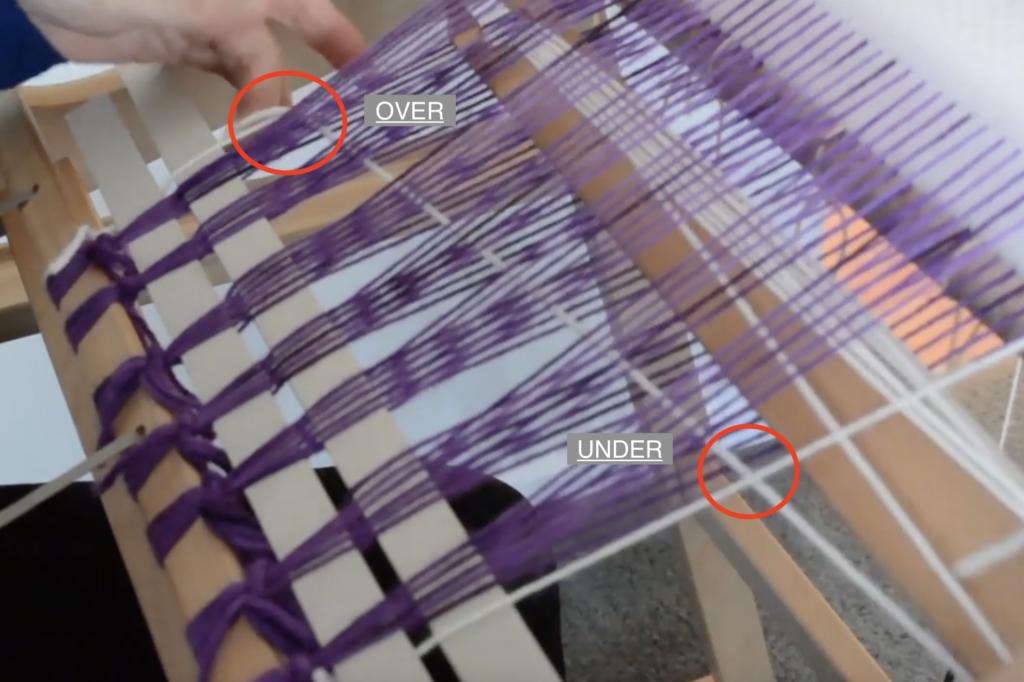

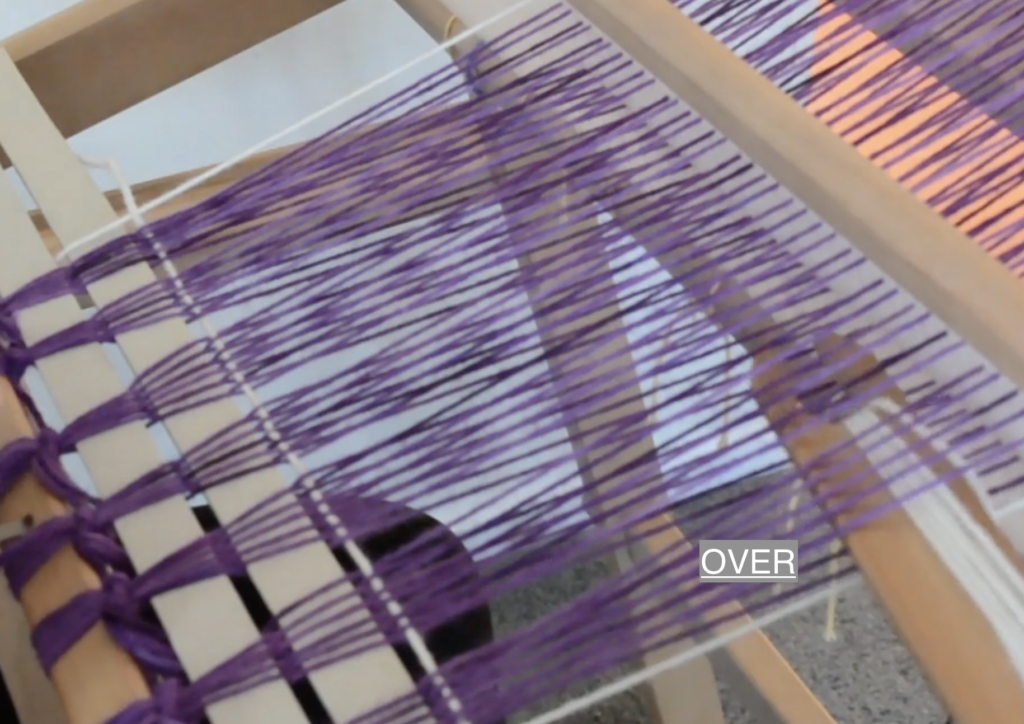

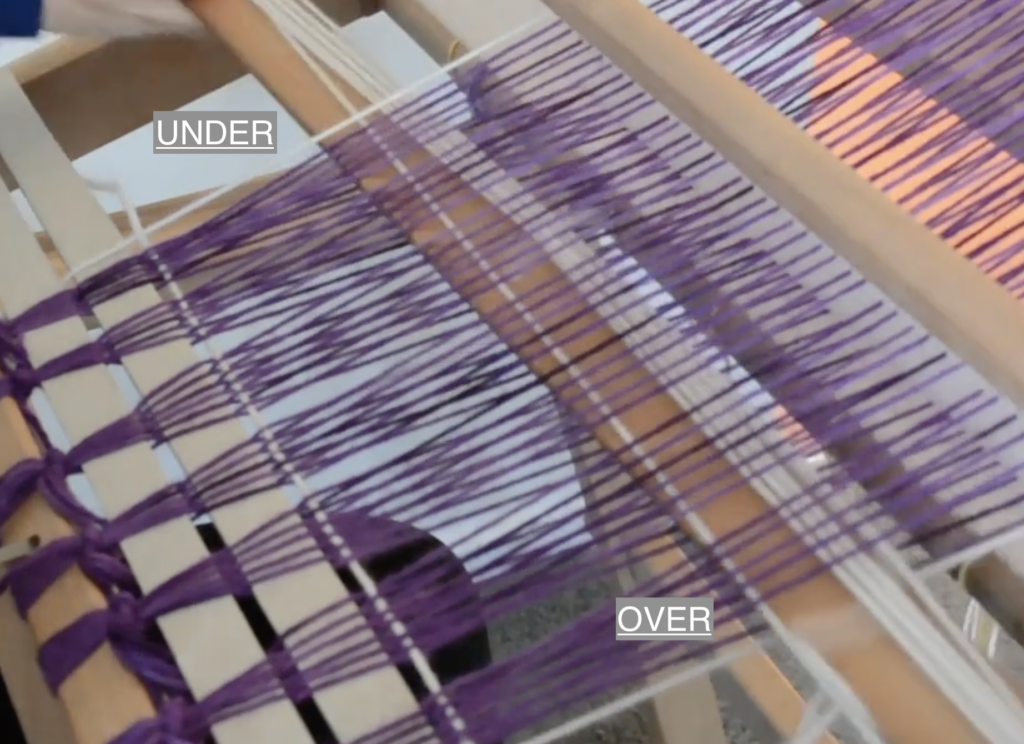

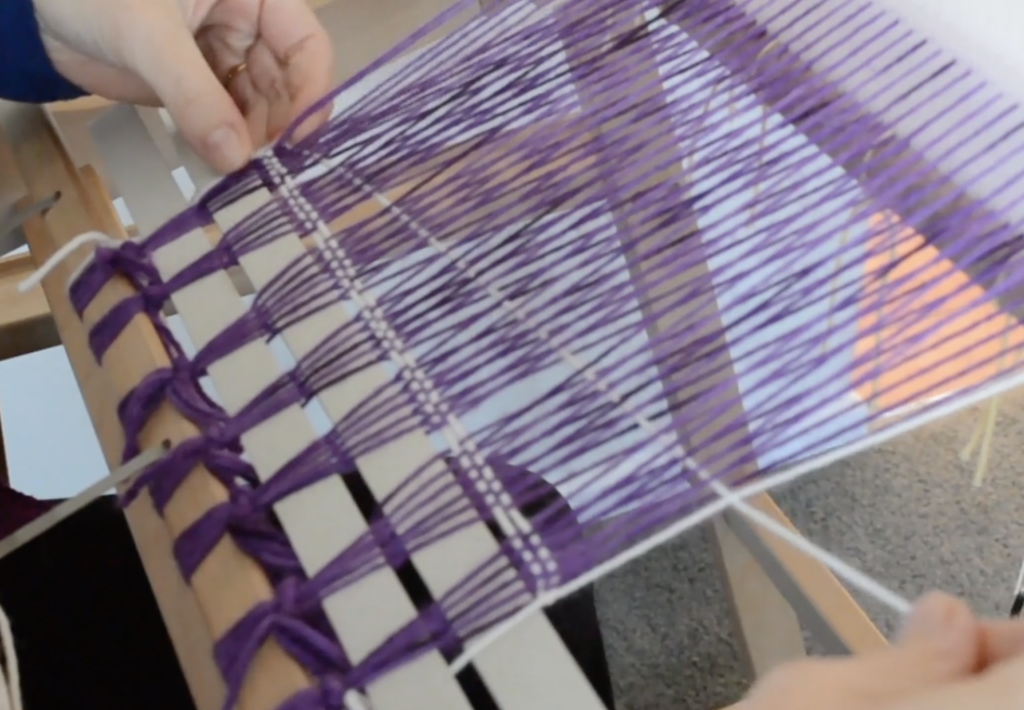

Table looms are often the entry point for multi-shaft weaving and this was certainly the case for me. Instead of using your feet, you use hand-operated levers (usually located on the side or the top of the castle) to lift your shafts.

The Pros:

- Portability: These looms are frequently much smaller, lighter and can be moved easily, making them perfect for workshops. Most table looms have a foldable castle.

- Ease of Setup: There is no “tie-up” process, because basically, the shafts are permanently tied up. If you want shaft 1 and 3 to go up, you just flip levers 1 and 3.

- Visual Learning: It’s very easy to see exactly which shafts are raised, which is great for beginners learning to read drafts.

The Cons:

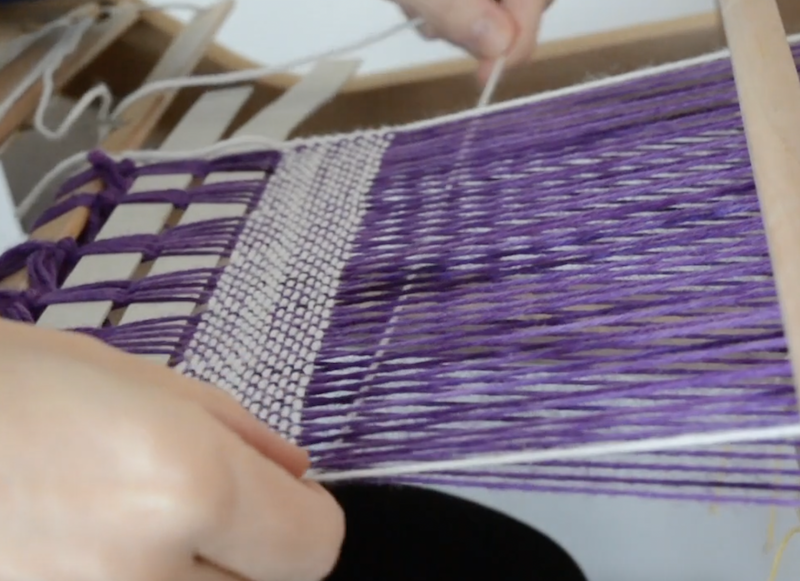

- Slower Speed: Every time you throw the boat shuttle, you have to take your hand off it to flip the levers. This breaks your weaving rhythm. It also means frequently putting the boat shuttle down to free up your extra hand.

- Physical Strain: Using your arms and shoulders to lift shafts for hours can lead to fatigue more quickly than using your legs. This can depend on the size of your table loom and how you have it set up.

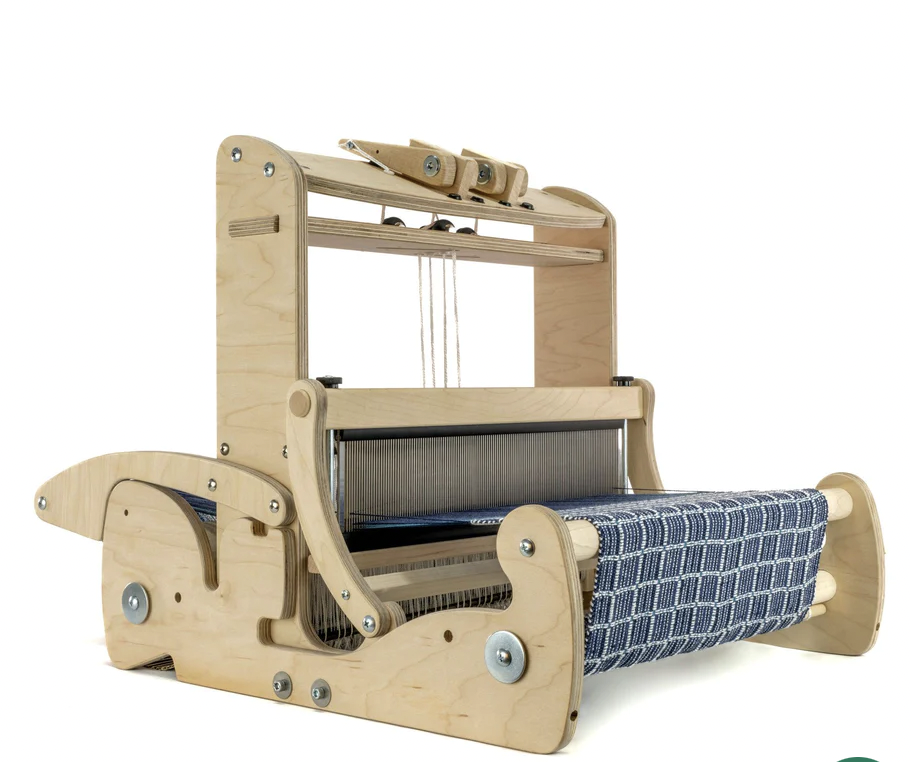

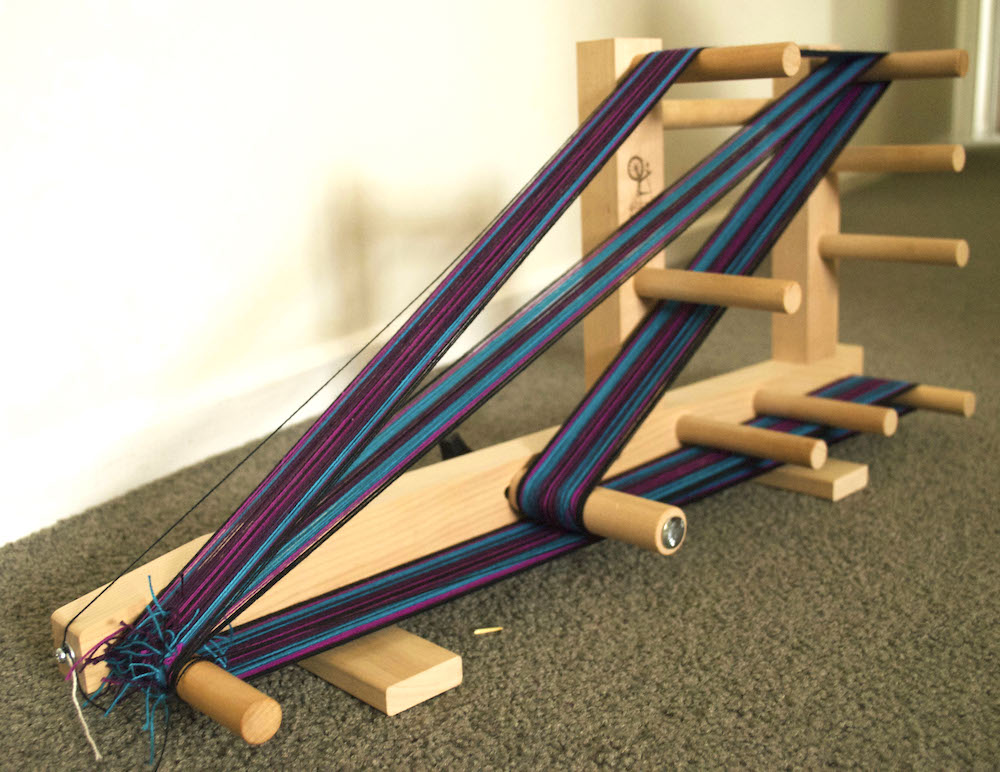

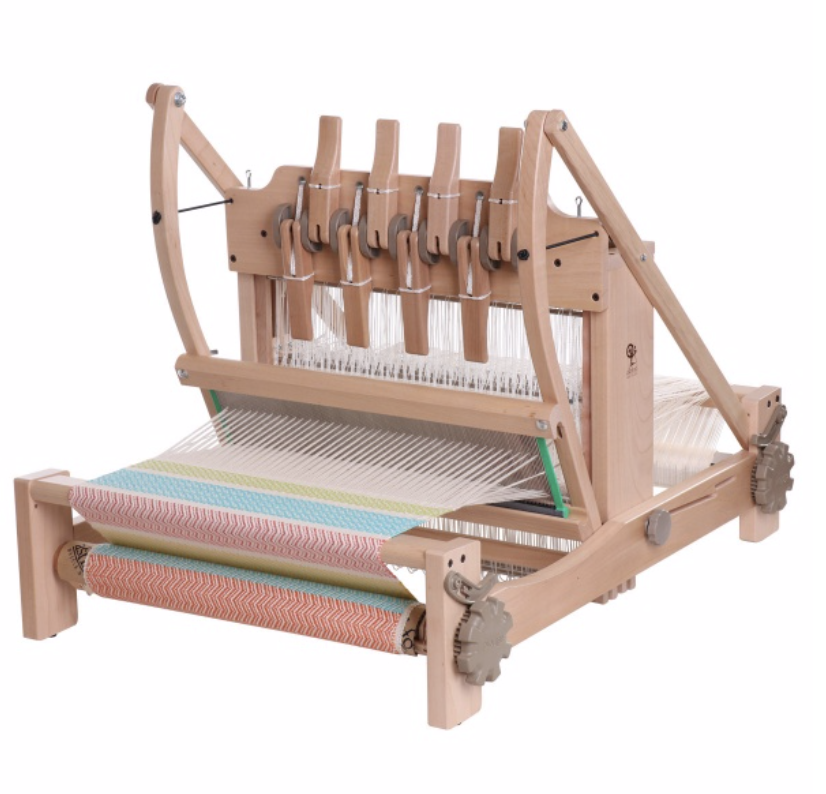

The Floor Loom Experience: Rhythm with Treadles

Floor looms are designed for production and ergonomic flow. By moving the shaft control to your feet, your hands are free to focus entirely on throwing and catching the shuttle.

The Pros:

- Speed and Rhythm: Once you get into a “dance” with your treadles, the weaving goes significantly faster.

- Ergonomics: Pushing down with your legs is generally less tiring than lifting levers with your arms, allowing for longer weaving sessions. Using your whole body to weave can feel very balanced.

- Complexity Made Easy: While the tie-up takes time at the start, once it’s done, a single foot press can lift (or lower, depending on your loom type) multiple shafts at once.

The Cons:

- Space: They require a dedicated space in your home.

- The Tie-up: Crawling under the loom to tie treadles to shafts can be a bit of a workout! If you have back issues, the less time you spend hunched on the floor, the better!

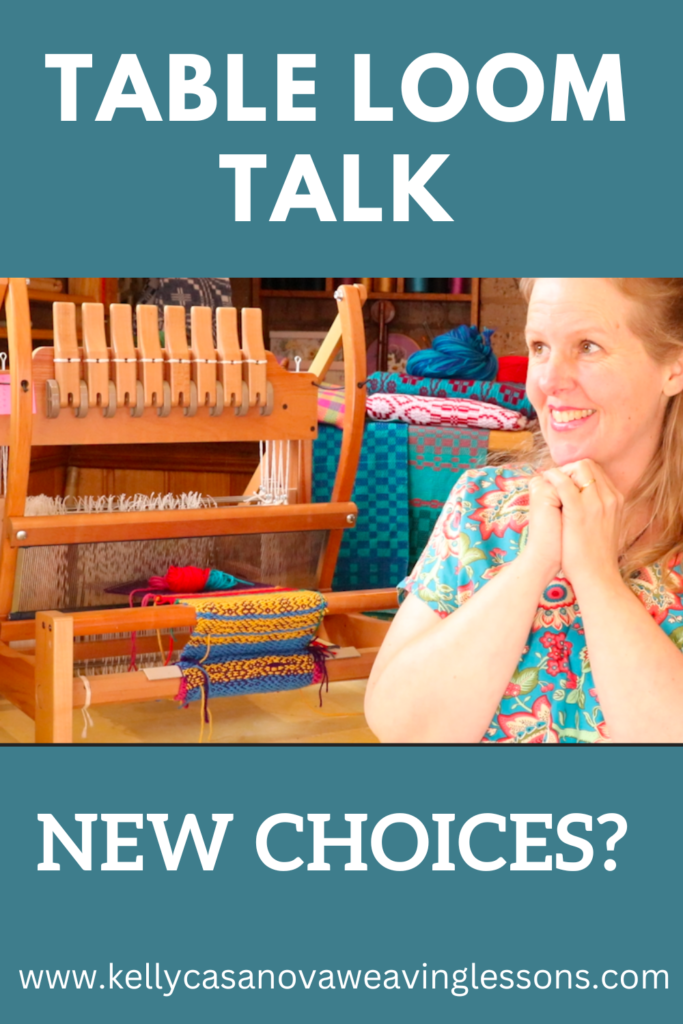

Which Should You Choose?

If you are short on space or want a loom you can take to guild meetings, the Table Loom is a fantastic tool. However, if you find yourself wanting to weave long projects (like yardage for clothing or multiple towels) or if you want to find a faster “flow,” the Floor Loom is the way to go.

Tips For Weaving with Levers

I always recommend to purchase a stand with your table loom. Although it’s an extra expense, it is worth the investment long term.

Weaving with your table loom on a stand allows you to get very close to the loom and levers, providing a greater level of comfort and less arm/shoulder/neck fatigue. You can usually adjust the height of the stand too (or use a height adjustable chair) to get the perfect height for you.

You can speed up your weaving process a little by flipping more than one lever at a time. Once you get used to it, you will find yourself doing this naturally.

Using a table loom with levers means you don’t have to be “treadle conservative”. Your levers are not limited to a specific tie up like treadles are, so pattern explorations are much more possible.

Tips for Weaving with Treadles

Opt for “light treadling” when you can. What this means is try not to tie too many shafts up to any one treadle, as this will make the treadling heavy and hard on your back.

If you find the number of treadles on your loom (or lack thereof) a bit limiting, try a skeleton tie up or use a treadle reducer. This can expand the kind of patterning you can achieve.

For some types of looms (like a countermarch) the tie up can be quite cumbersome and difficult. To avoid time spent cramped on the floor inside your loom, look into options like the Top of the Lamms method. Also put a lot of thought into the type of floor loom that will work for you prior to purchasing. You may want to look at the “not time spent on the floor” looms like the Louet Megado Dobby (my dream loom!)

Download Your Free Weaving Draft!

To help you practice on either setup, I’m sharing one of my favourite weaving drafts. This is a versatile 4-shaft M & W Twill that works beautifully whether you are flipping levers or stepping on treadles.

If you have weaving software and would like the WIF file, grab that here:

Don’t forget to check out the Youtube video for more information on levers and treadles!

Until next time…

Happy Weaving!

- This post contains affiliate links. For more information, please see my disclosure policy.