It’s that wonderful time of year again, when thoughts start turning to festive project and gift ideas.

A number of years ago I released a How to weave Reindeer on a rigid heddle loom on Youtube and it has proved to be very popular! In that video we use pick up sticks in front of the heddle to achieve the shapes we need to build some little reindeer.

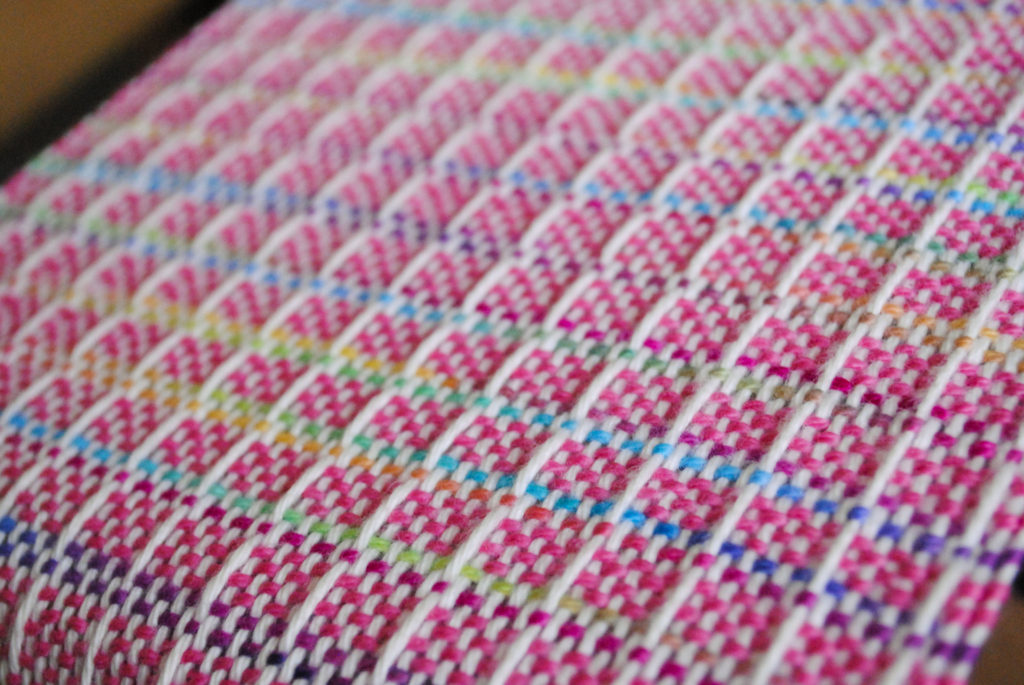

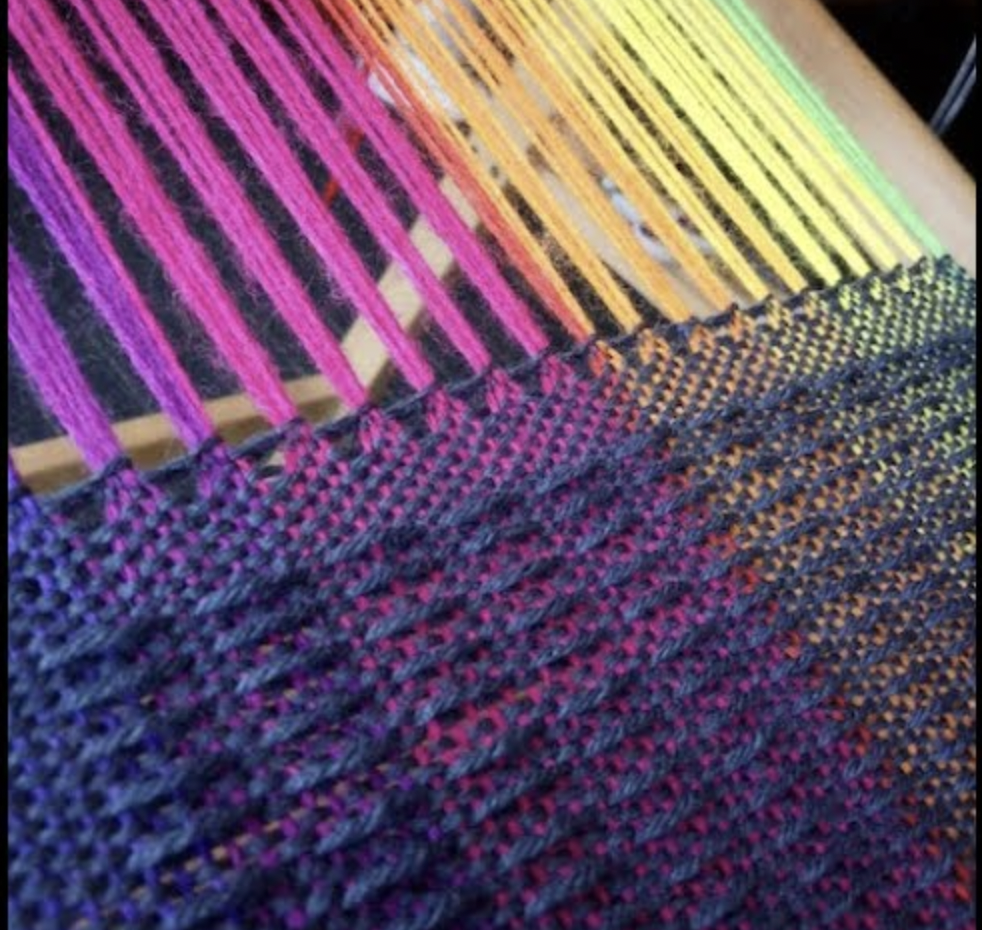

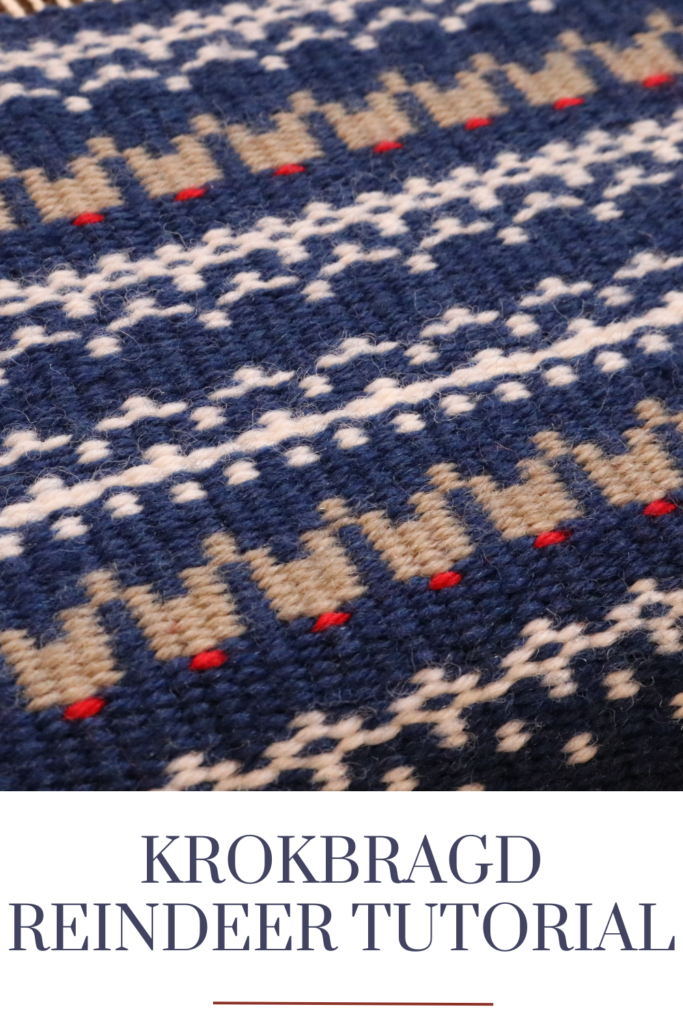

For my Christmas video this year, I decided to again weave reindeer but use a different weave structure for a different look. I already had my Sampleit loom warped for a krokbragd sampler so I set about designing some cute reindeer ensconced in a lovely Fair Isle inspired border.

This tutorial uses 4 colours for the weft – navy, white, red and beige. I used Bendigo Woollen Mills Luxury 4 play, which is a fingering weight wool. The warp should be a strong and thinner than the weft, I use a #12 seine twine.

Be sure to watch the free Youtube tutorial so that you can follow the weaving sequence along with the printable PDF.

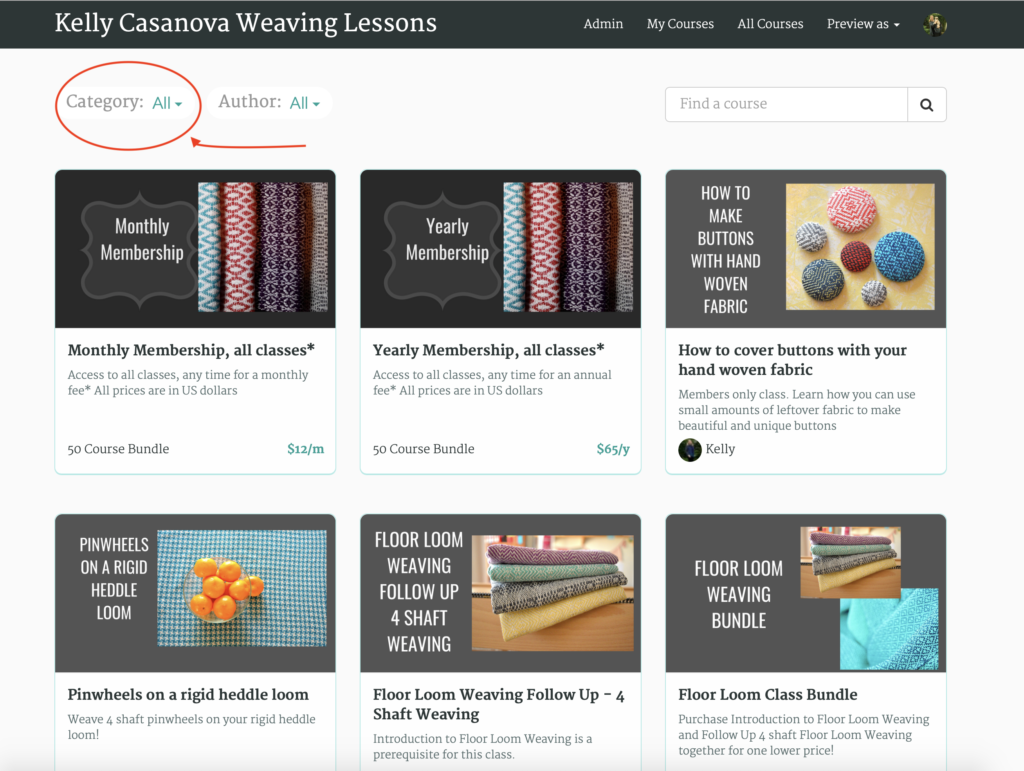

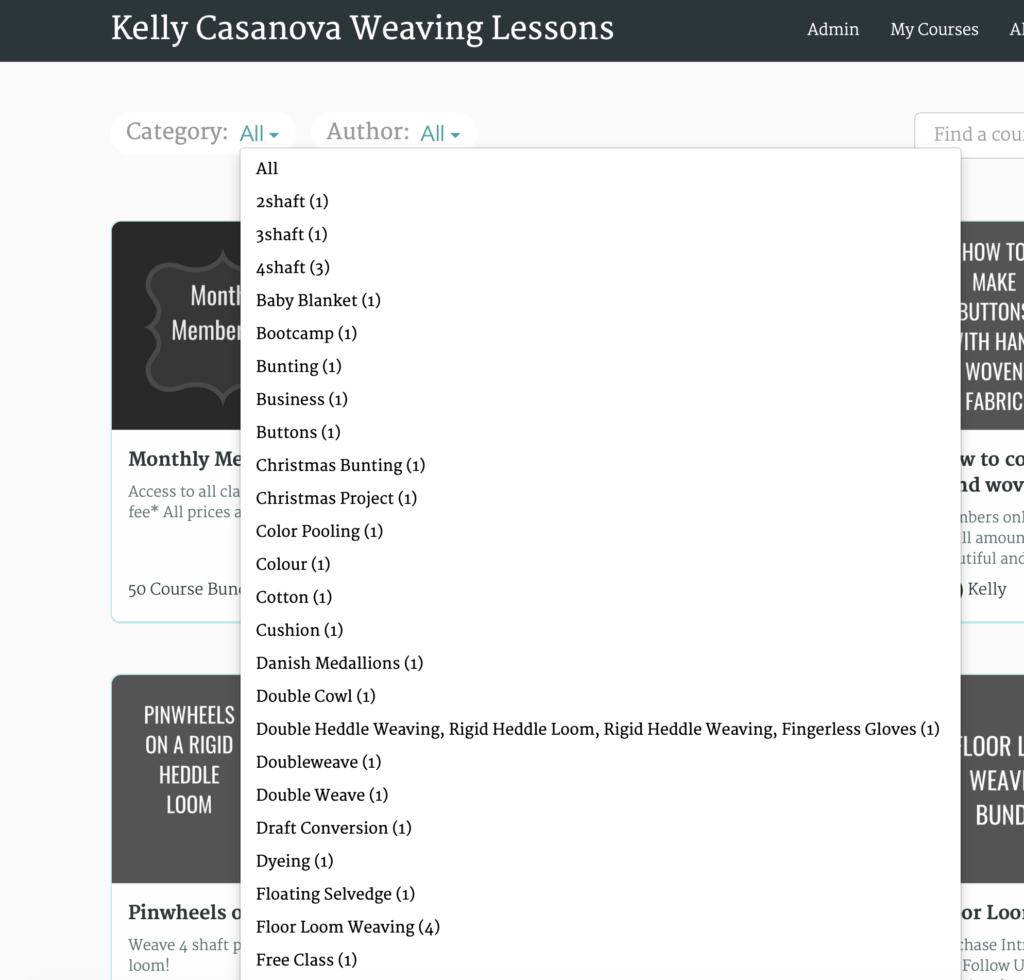

If you’re looking for further krokbragd learning resources, check these out:

*This post contains affiliate links. For further information, please see my disclosure policy

Until next time…

Happy Weaving!