It’s hard to believe that 3 years have passed since I began my Online Weaving School. Many of you have been with me for all of that time and longer, but if you’re new here, I’d like to tell you a little about my teaching journey.

*This post contains affiliate links

I’ve always been a creative person but making things with my hands became more important to me when I found myself an at home Mum with 4 children. The urge to relax and create became very strong and somewhat vital. I needed that quiet, meditative time away from my regular daily duties.

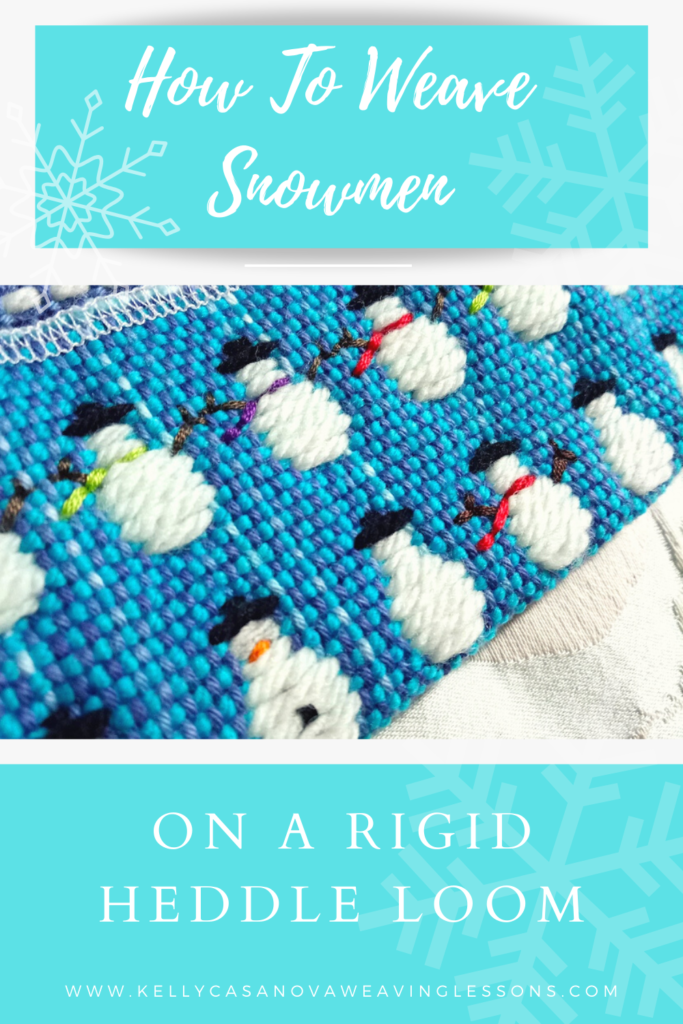

I started with embroidery after my mother in law gifted me with some vintage supplies. Then I got a sewing machine and started sewing clothes for my kids. From there I started making dolls. This began my relationship with Etsy, where I sold my dolls. Then bear making, quilting, knitting, spinning, dyeing and weaving. Many of these were learned books, some from just teaching myself and some (especially knitting) from Youtube. Youtube was just becoming a thing at that time. When I came to weaving, I found it the perfect culmination of so many of the arts and skills I had already been practicing for years. When I found weaving, I felt like I had come home.

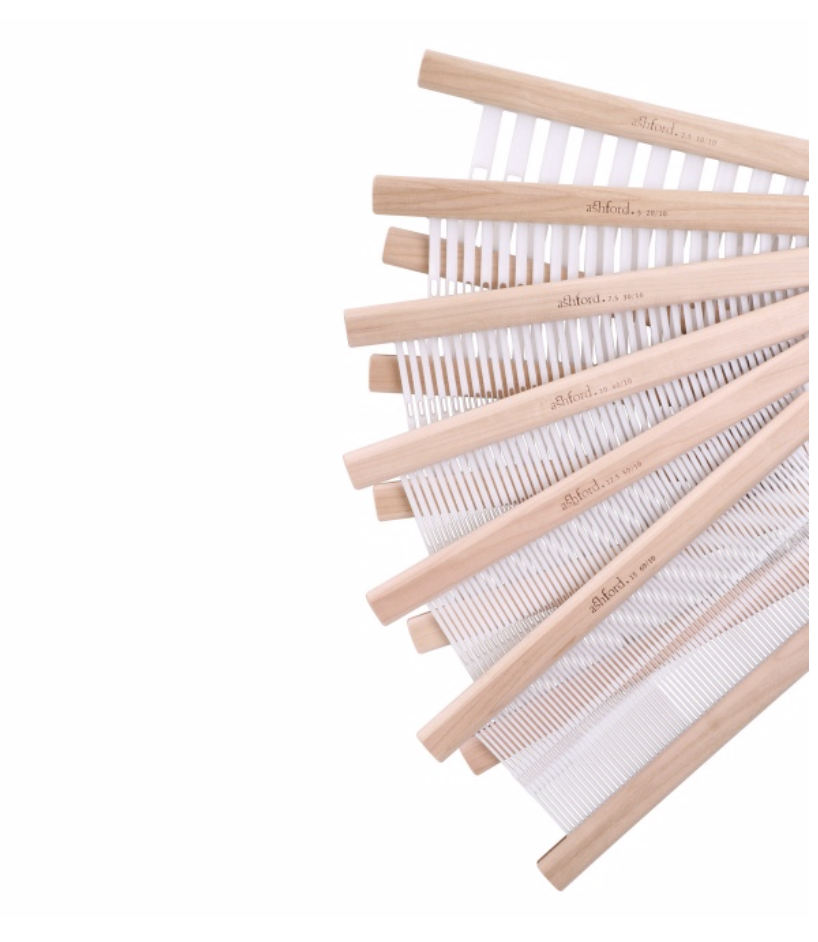

After I had been weaving for some time and felt very confident at my rigid heddle loom, I felt that I really wanted to share some of the wonderful things I had learned. I was almost bursting with excitement and passion but I didn’t know any other weavers at all.

So I made a video and uploaded it to Youtube. I didn’t know anything about how to teach or how to use Youtube. My son helped me to film and edit to make the video passable. I expected nothing, I didn’t even think about whether anyone would be interested. I just thought it might help someone and I wanted to share.

As it turns out, that video is still helping weavers, 5 years later! People loved the video and asked for more. I made more. And I loved it. It was so rewarding to know that I could help others and share this passion for weaving.

After a while, my Youtube hobby was starting to cost a lot of money in materials and the meagre income from Youtube ads didn’t even begin to cover the expense. I was a stay at home Mum, homeschooling her children and relying on my husband to earn enough income to keep us fed and clothed.

So, using a Youtube paid channel, I started to (gasp! how could I even dare to!) charge for classes. This was a big mind shift for me. People wanted to pay me in exchange for classes!! I still ran my free channel, but the paid channel was a huge blessing. Now at least I could cover my expenses, even if I still wasn’t really earning anything extra. When the Youtube paid channels ceased to exist, I had a fairly sizeable following of enthusiastic weavers. And they still wanted more! So, I found Teachable and set up my tiny Online Weaving School and community.

3 years later, that “tiny” weaving school has grown to over 4000 registered users and 750 paid memberships and is still growing! I am still pinching myself. Thanks to the constant support from my wonderful and loyal students, I now provide the income for my family of 6. This is something I never would have dreamed could happen and I have learned so much. I would go so far as to say that having my weaving school has transformed me as a person – or perhaps better to say, it has formed me into the person I was meant to be.

Aside from all of the obvious benefits the success of the school has brought me are the less obvious blessings. The beautiful friendships and relationships I’ve encountered with weavers all over the world. The ability to help others not just to learn to weave, but to share other difficult life burdens. It is amazing to be in a position where you feel you can truly make a difference to the lives of others!

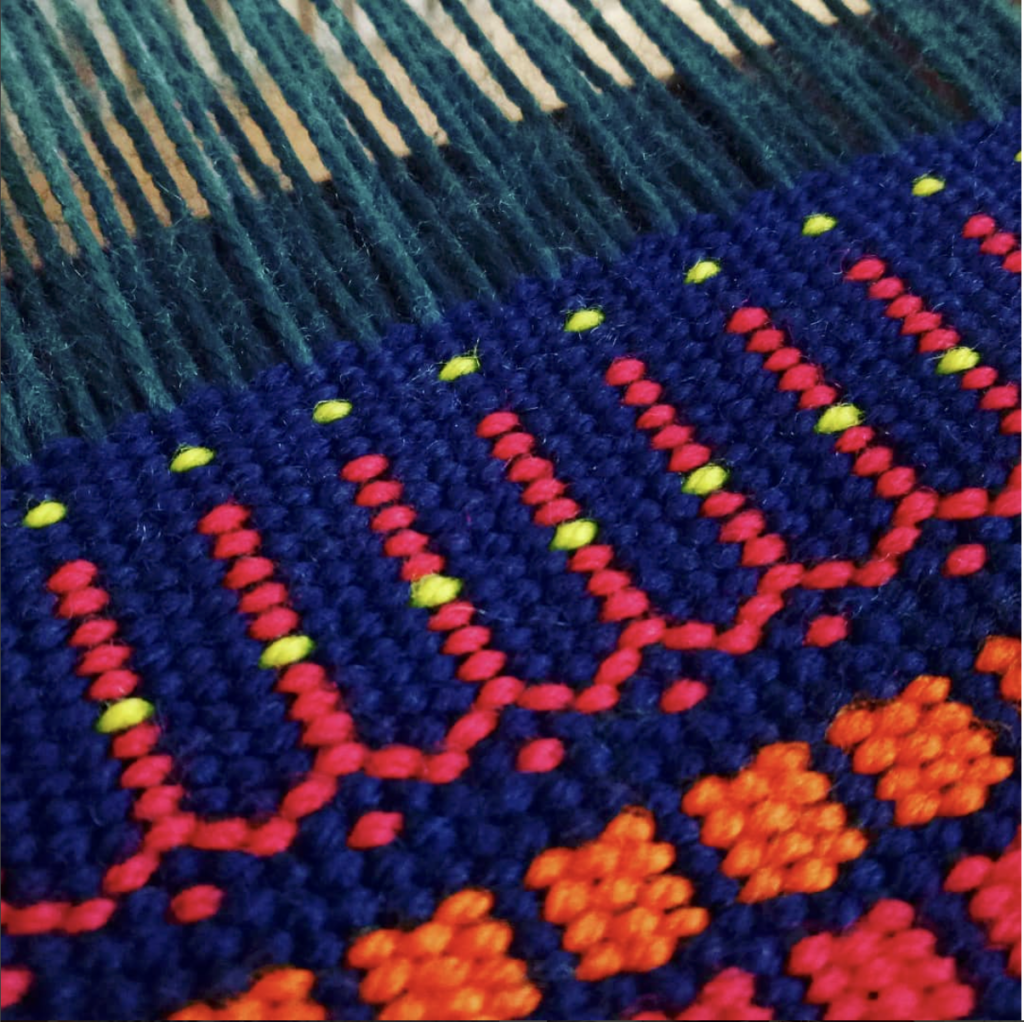

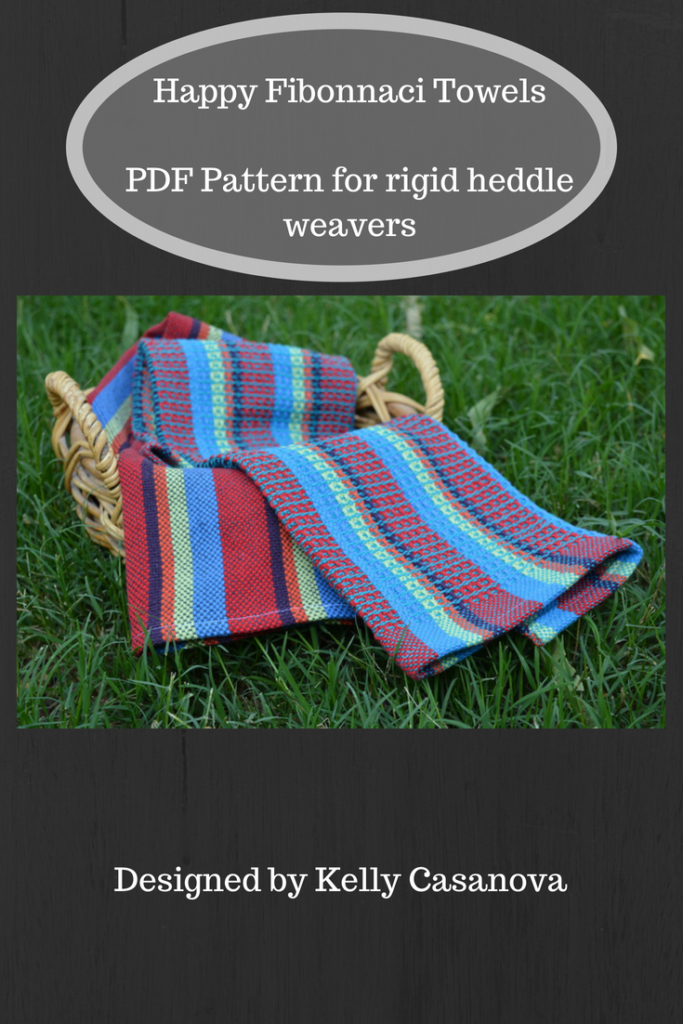

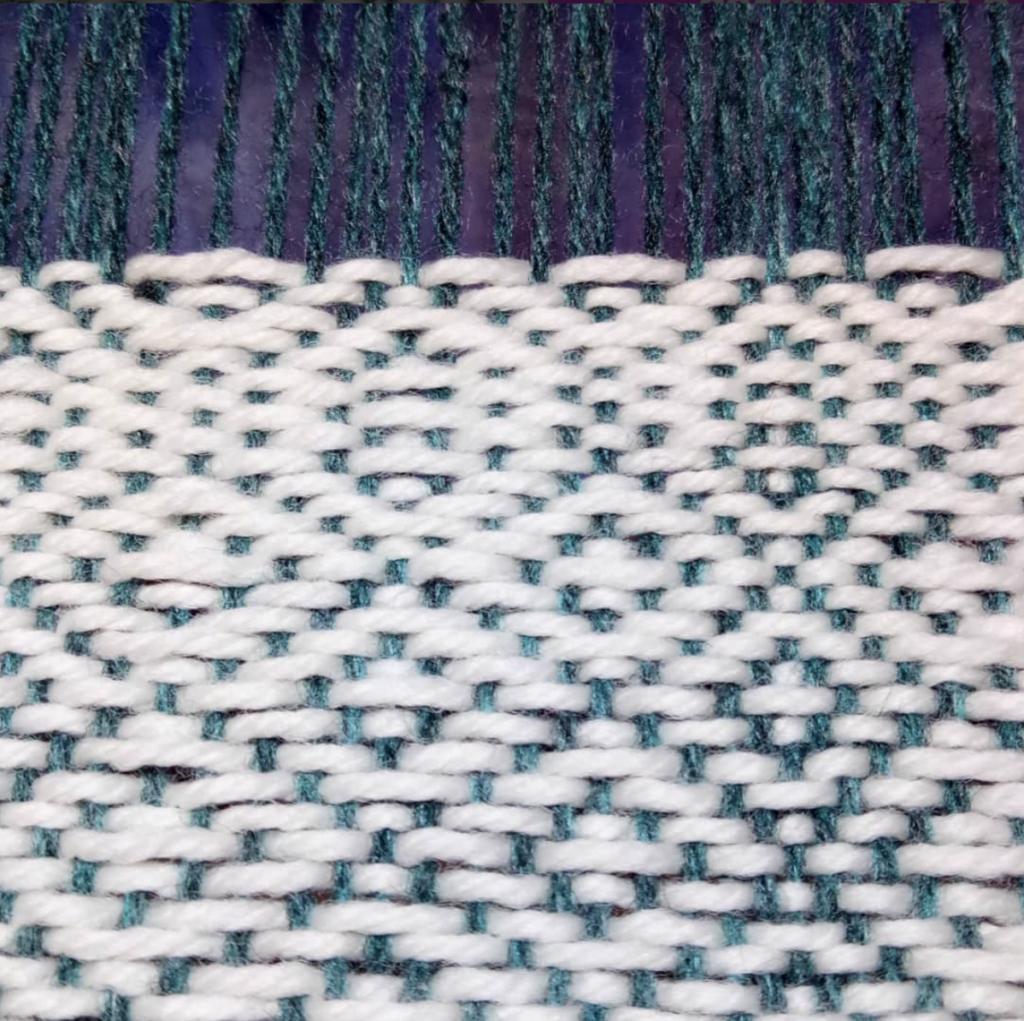

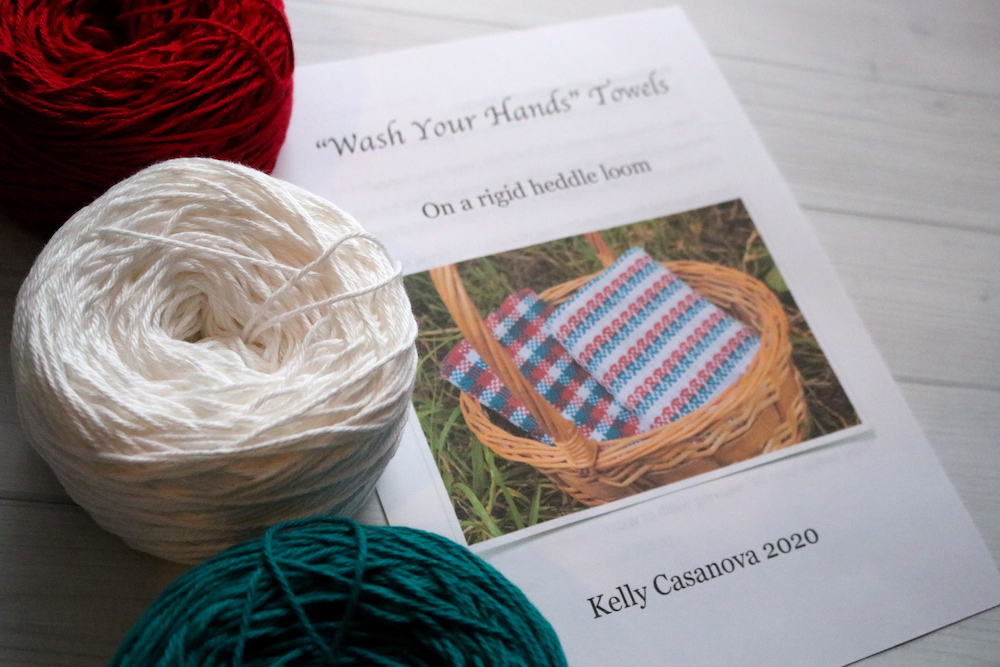

If you already know or follow me, then you will be aware of my recent free project, The Wash Your Hands Towels. I designed these towels in the time of uncertainty while the world was suffering from the effects (and still is) of the coronavirus pandemic. This has been a hugely popular project and seemed to come at just the right time for many weavers at home under lockdown. I’ve seen lots of different versions completed in a big variety of colours, it’s been wonderful to see.

So, I thought a very appropriate way to celebrate this 3 year milestone would be to give away a Wash Your Hands Towels Kit. This kit will be a one off, as I don’t have plans to make kits available for sale.

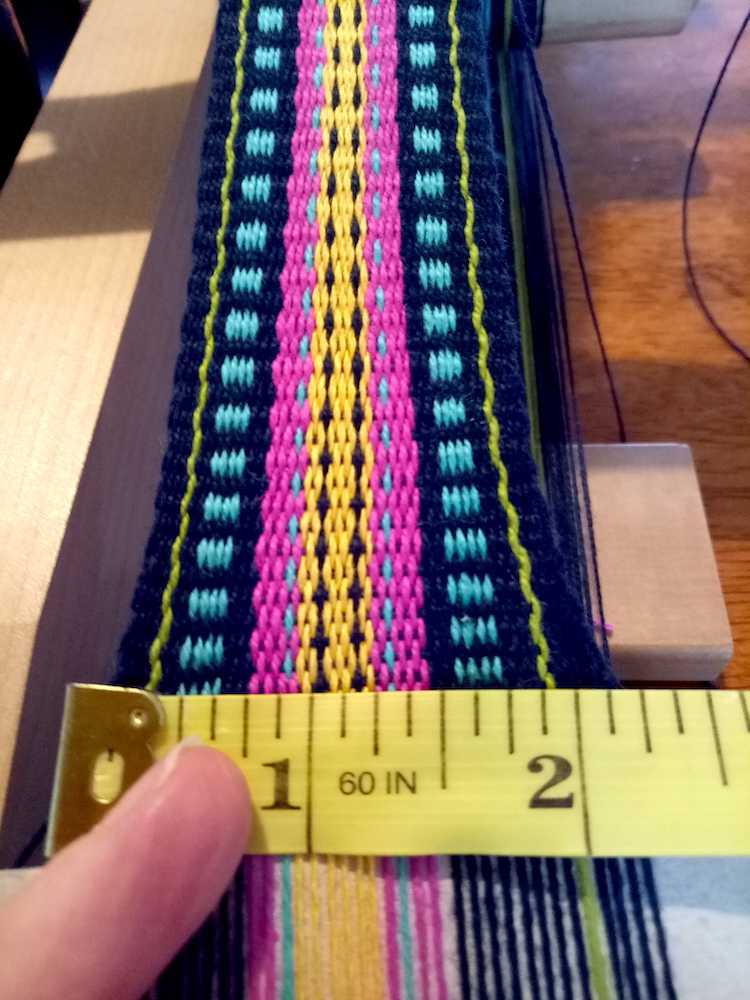

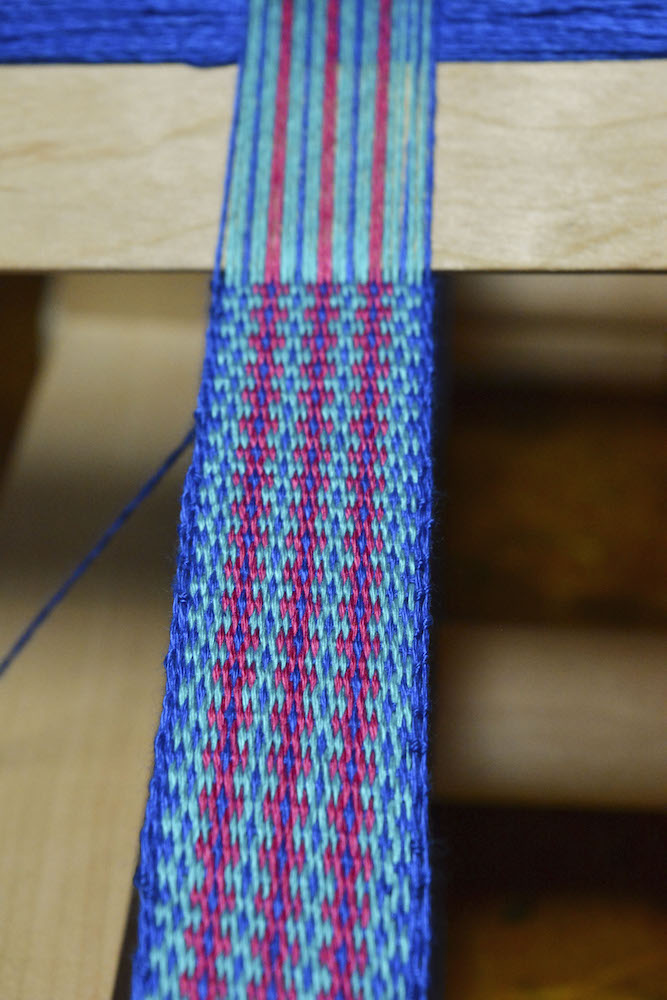

Included in the kit is all the beautiful Australian cotton yarn you need to make two towels plus a paper printed PDF. You use the PDF in conjunction with the video tutorial. If you wish to know what you need to complete this rigid heddle project, read this post that has all the details.

This giveaway is open to all, wherever you happen to be in the world. Entries are open until the end of this month of May 2020.

To enter the giveaway, please leave me a comment here (only comments on this blog post will be considered entries) and tell me why you would like to win.

Make sure you are on my email list to keep up to date with the giveaway and for the winner announcement.

I look forward to reading all your comments and drawing a winner!

THIS GIVEAWAY IS NOW CLOSED. CONGRATULATIONS TO THE WINNER – VEENA RAGHAVEN!

Until next time…

Happy Weaving!