As you probably already know, I’m a big fan of Ashford looms, I have four of them myself. I have found their looms to be reliable, easy to obtain, excellent learning tools and affordably priced.

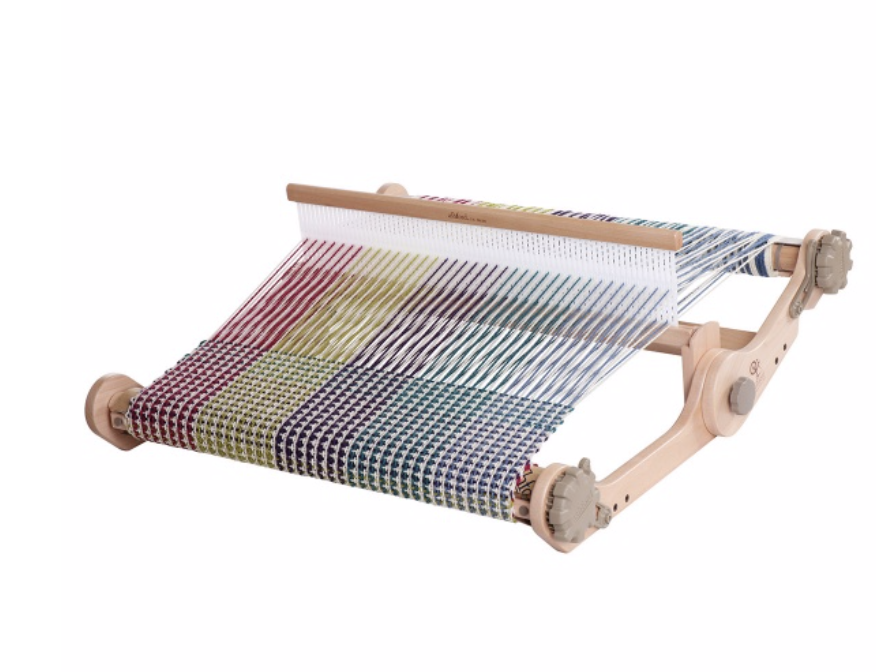

Ashford make a variety of looms including the rigid heddle, knitter’s loom, inkle looms, table looms and floor looms. They also make a big range of weaving tools, yarns and accessories, as well as all their other supplies for fibre artists.

*This post contains affiliate links. Please see my disclosure for more details.

I also love that the Ashford factory is based in New Zealand, my second favourite country (after Australia, of course!) and all the wood used is sourced from there too.

But today I want to focus on two of their looms that are very popular but also cause some confusion among new weavers – the knitter’s loom and the rigid heddle loom.

If you’re interested in knowing more about looms prior to purchasing, or just out of interest, I have a list of articles and videos that will be a big help to you.

Having never actually used a knitter’s loom myself, I knew it was time to call in some expert knowledge on the subject, and who better to answer my questions than Kate Sherratt from Ashford.

Kate was very generous in not only answering my questions but in giving me extra information for all of us to learn from. Let’s start with a little history of the rigid heddle and knitter’s looms:

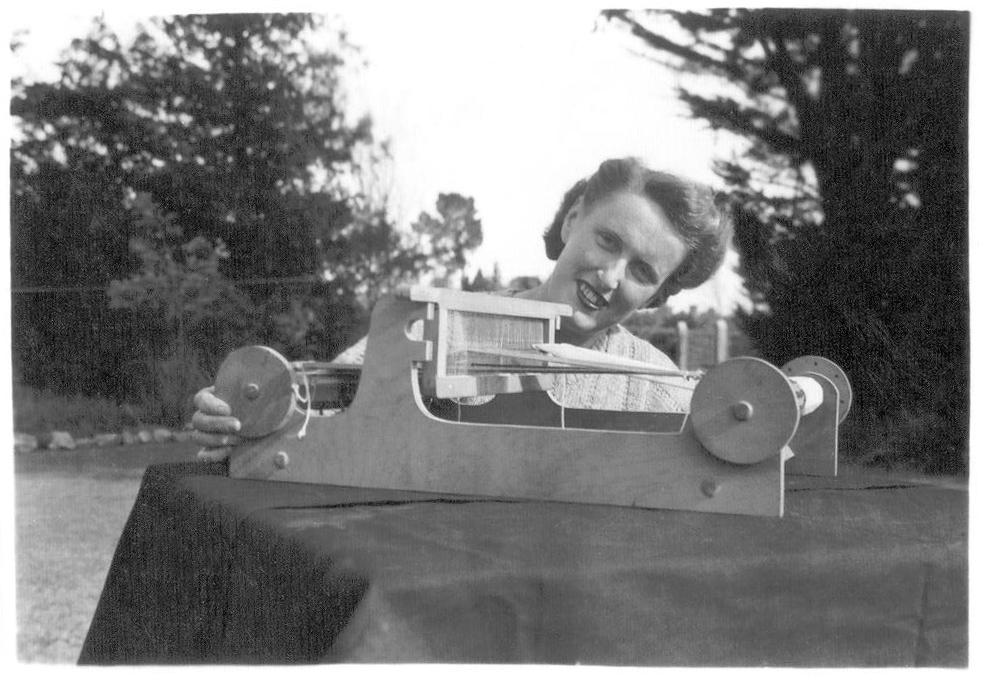

Ashford’s have been making Rigid Heddle looms for over 70 years. Pictured below is Richard Ashford’s mother, Joy with one of their early looms.

The Knitters looms are a more recent addition and were introduced in 2005. These looms are a type of rigid heddle loom but with some differences.

One of the aims of the knitters loom was to change the mindset that you can only weave with weaving specific yarns. It paved the way for knitters, who already had a healthy stash of knitting yarn, to ease seamlessly into weaving and continue to utilise the yarn they already knew and loved.

The release of the knitter’s loom brought a whole new wave of crafters and fibre artists into the weaving world. It had features that were very attractive to the brand new weaver who wanted to get up and weaving really fast.

It folded with weaving in place, it was lighter and more compact than previous rigid heddle looms, it had the factory lacquer finish and it was assembled.

So, which loom is the right one for you?

Ashford now make three types of rigid heddle looms – The Standard Rigid Heddle looms (RH), the Knitters looms (KL) and the SampleIt looms (SL).

Kate points our that all these looms are exactly the same in the way they function – you warp and weave on them in the same way.

The difference comes down to personal preference:

What size do you prefer? What do you intend to weave the most?

How much money do you want to spend?

How much space do you have?

Will you want your loom to be as portable as possible?

Let’s take a look at the differences between the three types:

RH come in four weaving widths 40cm (16″), 60cm (24″), 80cm (32″) and 120cm (48″).

KL come in three weaving widths 30cm (12″), 50cm (20″) and 70cm (28″)

SL come in two weaving widths 25cm (10″) and 40cm (16)

KL come assembled and have a factory lacquered finish and include a carry bag, making it very convenient to take to a class or outing.

RH come kitset and unfinished timber. This means you need to do your own lacquering, painting or waxing and assembling.

SL come kitset and unfinished.

KL fold in half for storage and transportation, can fold with weaving in place. Are made of the lighter timber.

RH are made of thicker more solid timber and do not fold.

SL are smaller, lighter and more compact – the most prominent difference is the depth of the loom – which will only effect the weaving when using non elastic yarns like cotton.

RH have more accessories available – the freedom roller, the table stand, and the warping pegs are exclusive for the standard rigid heddle looms.

What these three looms have in common:

6 different dpi reeds are available for all.

Vari dent reeds are available for all.

Stands are available for all.

They all can be warped the same.

They all can be woven on the same ways.

They all are affordable.

They all work extremely well, are well designed and do what they are supposed to do.

I also had some specific questions for Kate. These are things I am often asked by students.

*Can you use two heddles on a knitter’s loom?

All our rigid heddle looms come standard with the double heddle sideposts – as far as using three heddles go, I cannot personally comment as I have not tried it myself but I have seen people using three heddles on all our rigid heddle looms – including the SampleIts (see Amy McKnight’s recent posts).

I will also add here that I have several classes available on using more than one heddle. The most popular classes are Three Heddle Adventures and Weaving with Two Heddles

* Students have told me they have trouble when weaving the down shed on their knitter’s loom. They say that the heddle slips out of place.

On the Knitters loom the reed is held in the bottom position by the warp tension. It does not click into place or stay there when there is no warp on it, it is not supposed to. (the standard rigid heddle reed does not either, it only hangs from the upper rail, and as the KL has to fold the rails needed to be different).

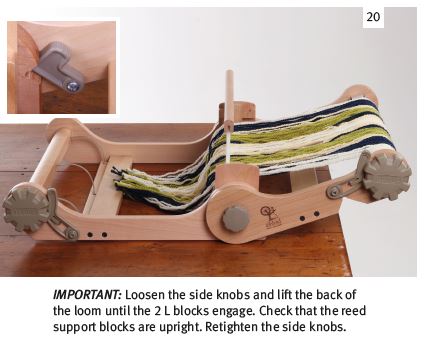

*Students have also mentioned that they need to angle the back of the knitter’s loom in order to weave. Can you explain this?

See the attached snippet from the Learn to Weave on the Knitters loom booklet (that comes with the loom) – the design of the loom, so it could fold etc, requires the back half of the loom to be angled up when weaving. This is probably the number one issue people have when starting out “help I have no shed” – to which the simple answer is lift the back up into the correct position.

*Are the heddle positions the same on each loom?

The heddle position are actually the same on all the looms – the distance is the same from the top to the bottom and to the neutral positions – it has to be the same as our reeds (the distance from the top rail to the eye and to the bottom rail) are all the same. And the sheds are the same…..

*How long a warp can you fit on each of these looms?

This does depend on a few things – yarn type, sett, warp separators etc. The limiting factor is the distance the cross rails are from the rollers – which varies from 7cm to 10cm. So you can fit quite a length!

*Is there anything else you think is important that people know about the looms?

You can do the same things on all the looms – there is not one that performs better technically – it really does come down to personal preference – and my personal preference is the good old work horse – the standard rigid heddle.

The question when buying a rigid heddle loom should not be “what can I do on a rigid heddle loom?” it should be what can’t you do! And although I do have Jack and Katie (and a couple of table looms) – my Rigid heddle looms (of course there are several) hold a special place in my heart – my love of weaving came not only from being taught to weave on a rigid heddle loom but more from all the possibilities there was from a simple piece of equipment – I know it sounds corny but there really are unlimited possibilities!

I get a little cranky when I here people say “oh you are limited on what you can do on a rigid heddle” – because really when you control the type of yarn (or fibre) you use, the colour you use, the texture you use, the sett you use, the patterns you create – the limits don’t really come from the loom they come for your imagination. And as 75% of the woven fabric in the world is plain weave – do you really need something else?

Wise words, thank you Kate!

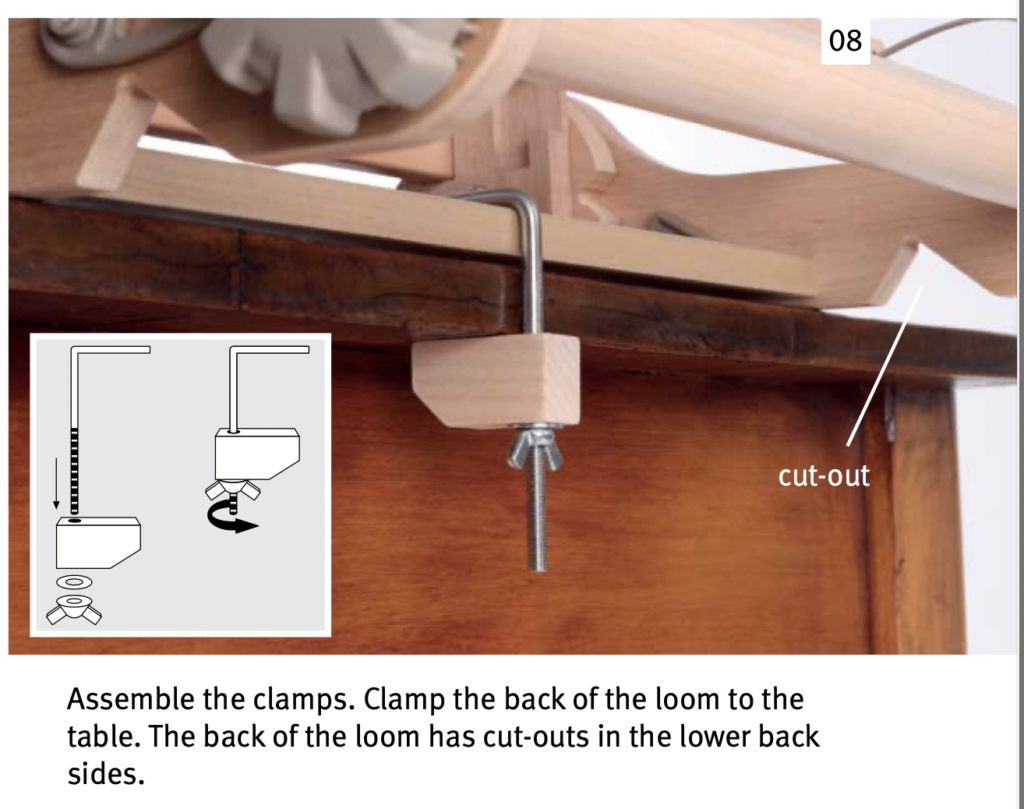

One more thing I want to clear up is how to clamp the knitter’s loom to a table. This can confuse new weavers, because although clamps do come with the knitter’s loom, there are no holes present to insert the clamps into, like there are with other RH looms.

The answer is very simple, as you can see here:

I hope this post has helped to clear up any confusion and answer some of your burning questions. Of course, you are welcome to leave any additional questions in the comments.

Do you own a knitter’s loom? A rigid heddle loom? A Sampleit? Was it a difficult decision for you? What helped you decide? Let’s keep the conversation going!

Until next time…

Happy Weaving!