Weaving

I have a rigid heddle loom, why would I consider buying a floor loom?

It is true that the Rigid Heddle Loom is capable of a lot (even an 8 shaft pattern if you really want to) but there are many reasons why I love to have both a RHL and a floor loom.

I wrote a series recently that compared different types of looms that you may wish to review:

The Rigid Heddle Loom

The Table Loom

The Floor Loom

Now, I said the rigid heddle loom is capable of weaving 8 shafts, but does that mean that I would actually want to? To achieve that would mean multiple heddles, multiple pick up sticks and a pretty painstaking process that would have me leaping on to my floor loom in no time. Because the floor loom is made for this, it’s set up for more complex weaves, that is it’s job. So, while the RHL can be utilised for more complex weaves, that doesn’t mean that it’s the ideal choice.

Next, the RHL has yarn size limitations. The smallest dent heddle currently available is a 15 dent by Ashford. Yes, you can still double threads or use extra heddles to increase the available sett, but that is another difference to a floor loom and a consideration if you like to weave with fine threads.

Finally, the floor loom is a full body experience. That sounds a bit weird and new age doesn’t it?! But what I mean is that you are using your head (eyes to read the pattern as you weave, if you need to), your hands to throw and catch the shuttle (your body naturally sways slightly from side to side as you get into the rhythm) and your legs (as your feet move or “walk” the treadles to operate the shafts). It’s actually a bit of a workout!

Because of this “full body” approach on a floor loom, you are able to operate many actions at once. And that is the real beauty of floor loom weaving, the harmony of actions that allow you to work fast to achieve sometimes quite amazing results.

Don’t forget that there are pros and cons to all types of weaving and I try not to promote one over the other because I believe each weaver needs to find the right fit for their particular needs. If it seems that I am promoting the floor loom in this article, it is only within context of answering a question.

To recap, why would I buy a floor loom?

1. Intricacy of pattern

2. Finer threads

3. Speed and efficiency

I hope this article helps you, thank you for reading!

Which loom to buy, part 3 – the Floor Loom

Which loom to buy, part 2, The Table Loom

My second loom purchase was an Ashford 8 shaft table loom. (Affiliate link).My back issues at the time were very troublesome and I didn’t want to invest in a floor loom only to find I couldn’t use it. It was a great decision for me at that time.

Table loom, rigid heddle loom, floor loom?

Lets start with the humble hero that I recommend most often for absolute beginners:

THE RIGID HEDDLE LOOM

The little champion of the weaving world! That is how I think of this humble loom anyway. I believe it’s thanks to this loom we have seen such an enthusiastic resurgence in weaving. You can view the rigid heddle looms I own (affiliate links):

Ashford 24″

Ashford Sampleit 10″

They come in a variety of sizes, are lightweight and portable, are much more affordable than table or floor looms, are customisable by adding a stand and extra heddles, plus they are simple enough for beginners to get up and weaving quickly. The ability to direct warp means you don’t need a warping board to get started. Threading is straight forward and easy. There is very little yarn wastage. You can adapt the loom to weave tapestries.You can even weave 8 shaft patterns on this loom (I’ve seen it done, but I don’t intend to do it myself – waaay too much work for me!)

That all sounds great right? Surely there must be some drawbacks to this loom?

Well, there are limitations to the rigid heddle loom. The tension, for example, is not like a floor or table loom. Weaving is slower, as you need to put your shuttle down after each pick in order to beat. I mentioned that you can weave up to 8 shafts, but it would take a lot of patience and mucking around that would have me personally reaching for my floor loom in a jiffy (though I realise that not everyone has that luxury!)

I don’t really think of these things as negatives, the rigid heddle loom has too much going for it to warrant any real criticism. What I have listed above are more differences as opposed to negatives.

Want to know more about the rigid heddle loom? You may wish to watch my free Rigid Heddle Loom/Table Loom Comparison video. I also have a huge range of videos for rigid heddle weavers or those interested in starting out on my Youtube channel, so be sure to watch, like and subscribe to ensure you don’t miss new videos.

I also have a big range of rigid heddle weaving classes available on my Online Weaving School, I recommend you taking a look!

I hope this article has been helpful to you, next time I will discuss table looms!

Towels just for moi!

Spring Table Runner Free Rigid Heddle Project!

What you will need to complete this project:

*A rigid heddle loom, 20″ or wider

*A 7.5 dent reed/heddle

* 2 x stick shuttles, at least as long as the width of your project

*A pick up stick, longer than the width of your project

*A double ended reed and heddle hook or a separate threading hook and reed hook

I know that many of you do not have access to the same yarns that I do. Let’s have a look at some suitable yarns you could use to complete this project:

For the 10 ply/ worsted/aran weight:

Bendigo Woollen Mills Cotton 10 ply

Knit Picks Dishie Worsted cotton

Hobby Lobby I Love This Cotton

For the 8 ply/ light worsted/dk weight:

Bendigo Woollen Mills Cotton 8ply

Cestari Old Dominion 100% cotton

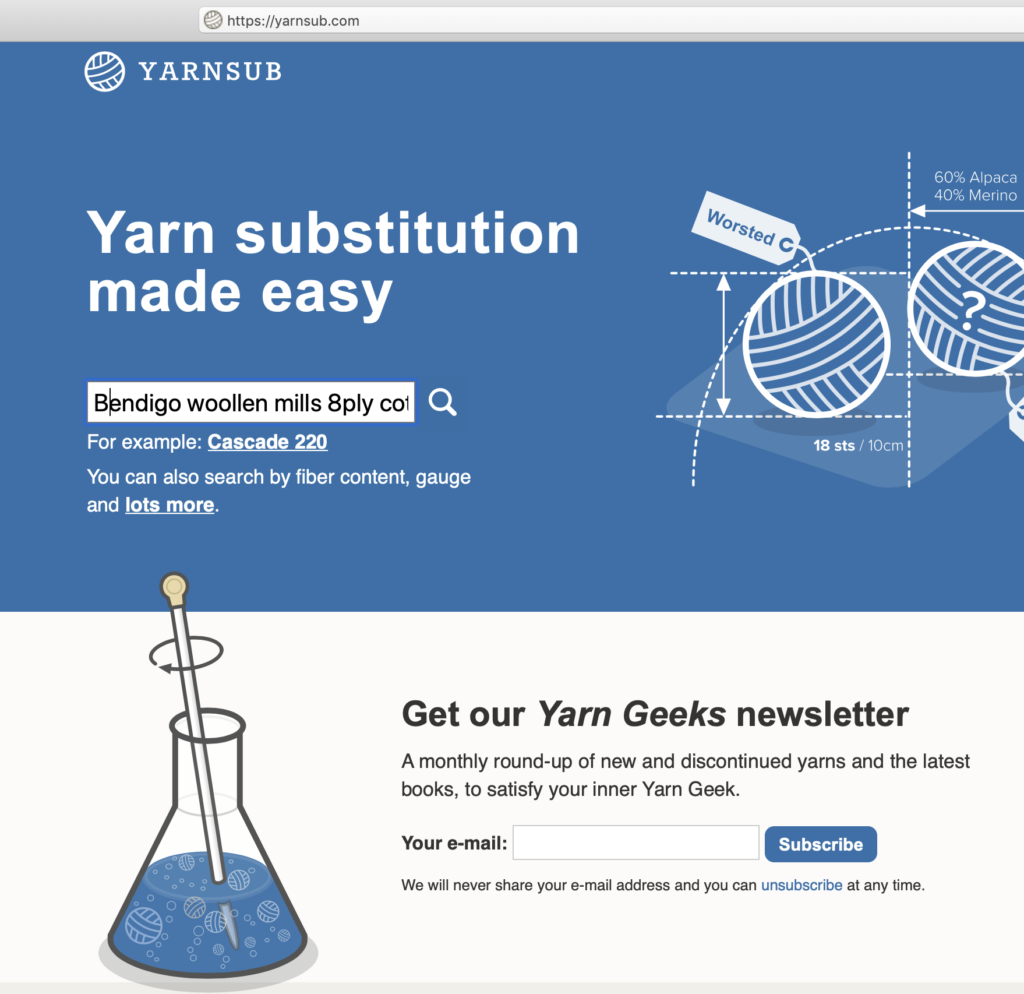

Yarnsub.com is also an excellent resource for finding a variety of yarns with similar characteristics to what I used. It is a simple site to use, but if you’re unsure, here is an example:

On the homepage, enter into the search box the yarn than you wish to substitute. Here I’ve entered “Bendigo Woollen Mills 8ply cotton”.

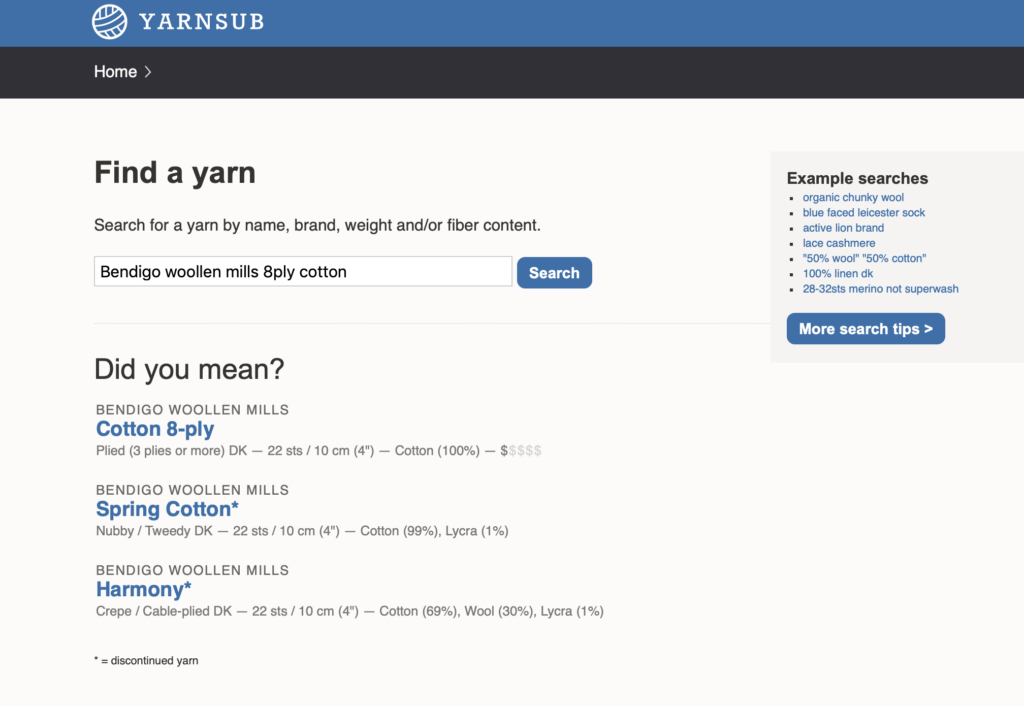

Hit “enter” on your keyboard or click on the little spy glass. Choose the correct yarn from the list below. In this case, I will click the top yarn.

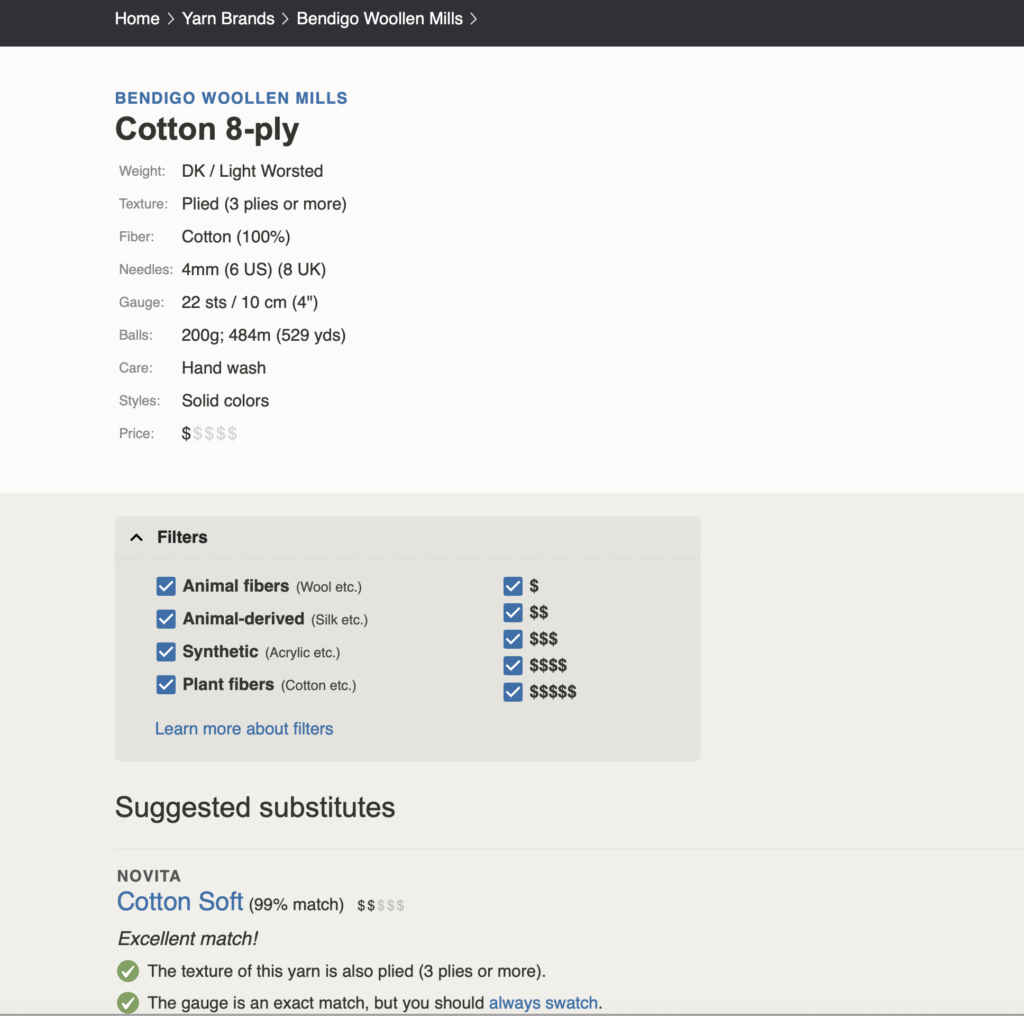

When you see this page, start scrolling down for all of the listed possible matches or near matches. This particular search gave 50 results!! You will see after each suggested yarn there is a percentage match – that will tell you how well the suggested substitute matches your original search. It’s brilliant!

You can of course substitute colours depending on availability and individual tastes. One of my favourite runners that I’ve seen is this one, woven by Juliet.

A very different colour scheme is used here, but still feels very Spring like and is absolutely beautiful!

The entire playlist of videos for the class can be found here-

The video series plus PDF can also be viewed at my Online Weaving School, if you prefer.

I really hope that this Spring Table Runner brings a little freshness to your table and joy into your home!

If you have any questions or comments, please leave them under this post, I would love to hear from you.

Until next time…

Happy Weaving!

Fear of the loom!

I know people who have abandoned a new loom into a corner, a spare room or (dare I speak it?) a dusty garage. The fear is too great to make a start and they feel they have failed before even beginning.

I say that I am surprised, but I really shouldn’t be. All it takes is a few moments of thinking back to when I was a new weaver. I was so excited by this beautiful piece of equipment, but silently terrified! What a privilege, but what a responsibility!

So, how to rid yourself of the fear? It’s actually very simple. You arm yourself with the knowledge you need and you practice! Read books, find resources, take courses, find weavers, join groups and network. And practice! Start simple and work your way up. Think of how an athlete trains. That is you, at your loom. Training, practicing, learning from mistakes and building knowledge.

If you do this, the magic will start to happen. That magic is CONFIDENCE! And with confidence, the sky is the limit.

If you are at that frozen with fear stage with your loom, perhaps you need some extra resources to help you out.

My Youtube channel has a plethora of videos to help you get started in weaving.

My Online Weaving School is a great place for learning and gaining confidence.

My Facebook Group is a friendly and welcoming place for weavers of all levels.

I hope this post will inspire you to go out there and weave beautiful things!

New Introduction to Floor Loom Weaving course

DIY natural hand softener

Do you ever have problems with dry hands that become rough?

Gardeners are very familiar with this issue, but it can also happen if you frequently use soap for hand washing or are often in a heated environment.