Recently I purchased a Lavievert Toy Weaving Loom.

My motivation for doing so was twofold – firstly, I was curious and thought it might be a fun experience and secondly, I’m always on the lookout for ways of advising newer weavers on ways that they can get into weaving more economically.

*This post contains affiliate links. For further information, please see my disclosure policy.

Naturally, before I recommend any product I need to first use it and review it myself!

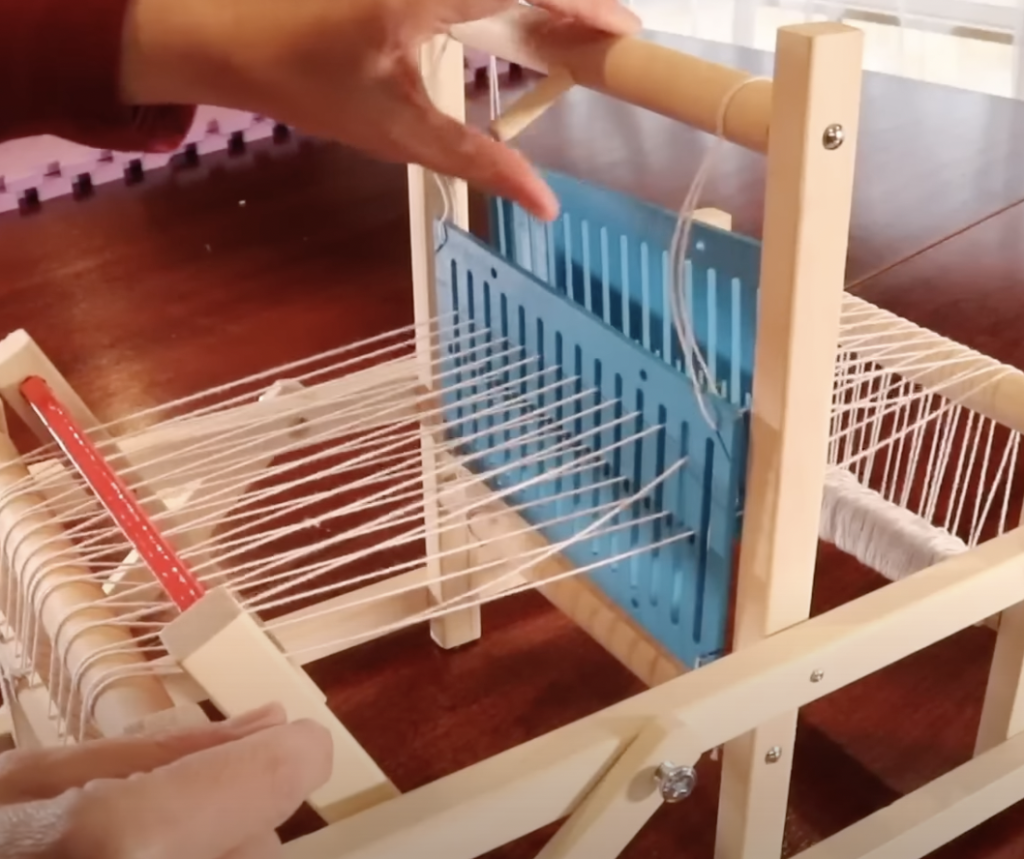

The only other toy or children’s loom I’ve used is a very cheap and basic frame loom, so this loom from Lavievert seemed quite a step up and more similar to a rigid heddle loom.

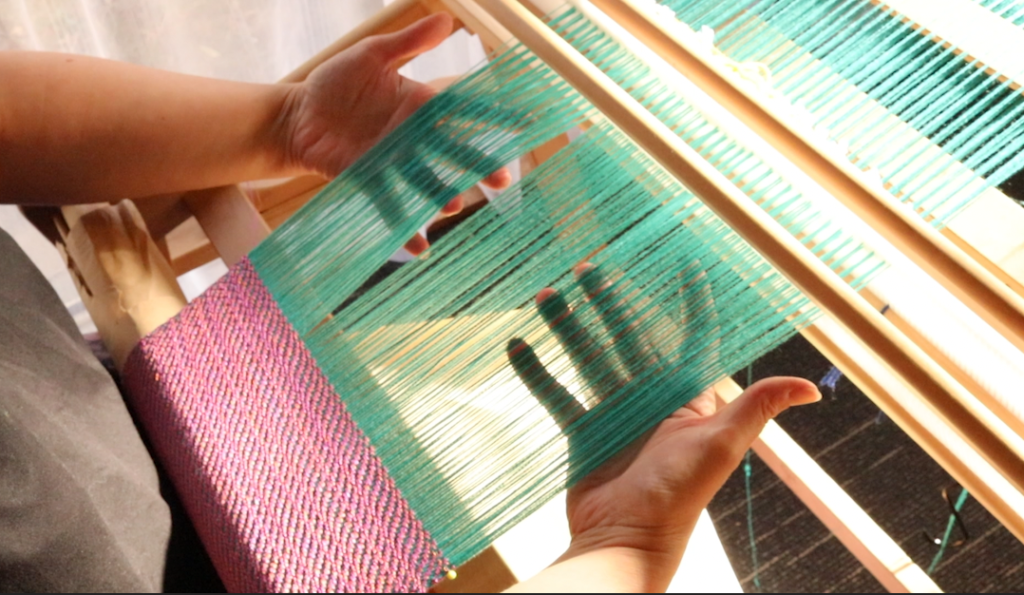

This loom is very small, compact and lightweight. The initial setup couldn’t really be easier – it comes pre-warped and simply unfolds and then is held in place by a couple of screws.

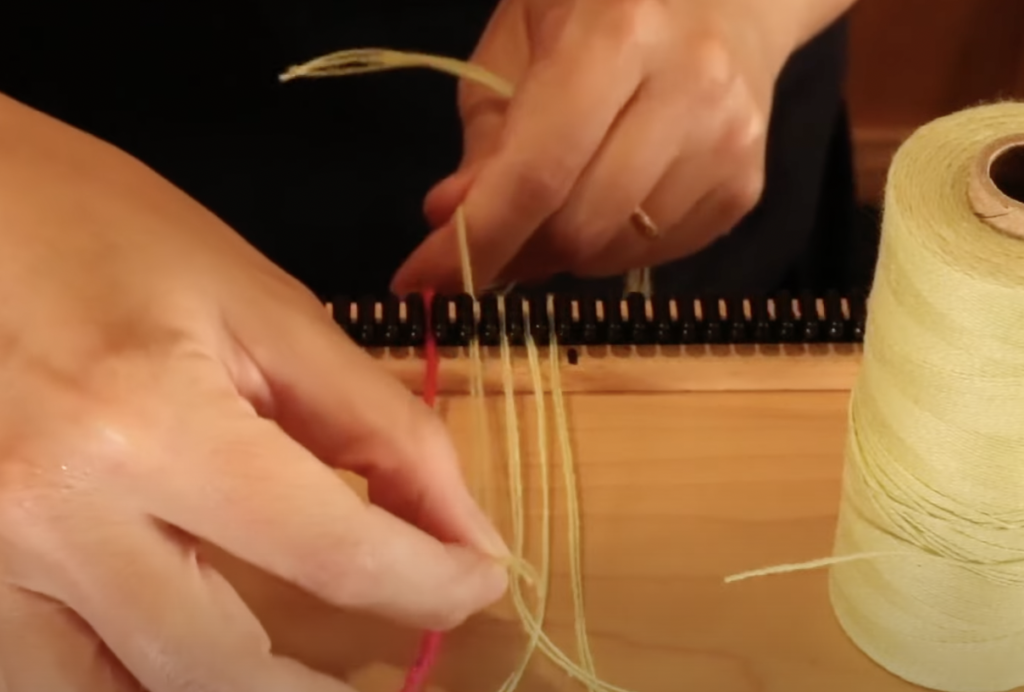

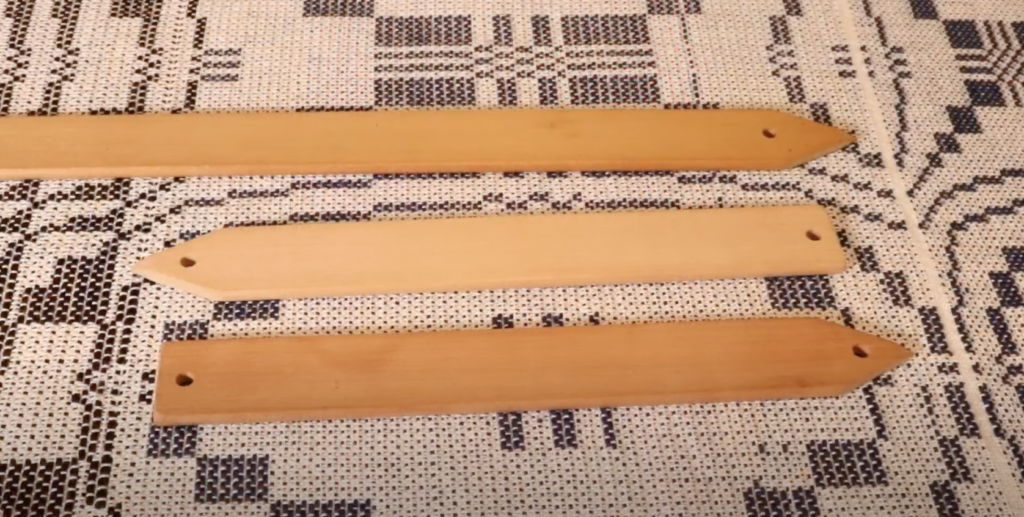

It also comes with 3 balls of acrylic yarn, 3 little stick shuttles (already loaded!) and a very basic instructions booklet. The booklet only really tells you how to unfold the loom, start weaving and advance your warp – there are no instructions for future warping, which could have been a useful addition to new weavers!

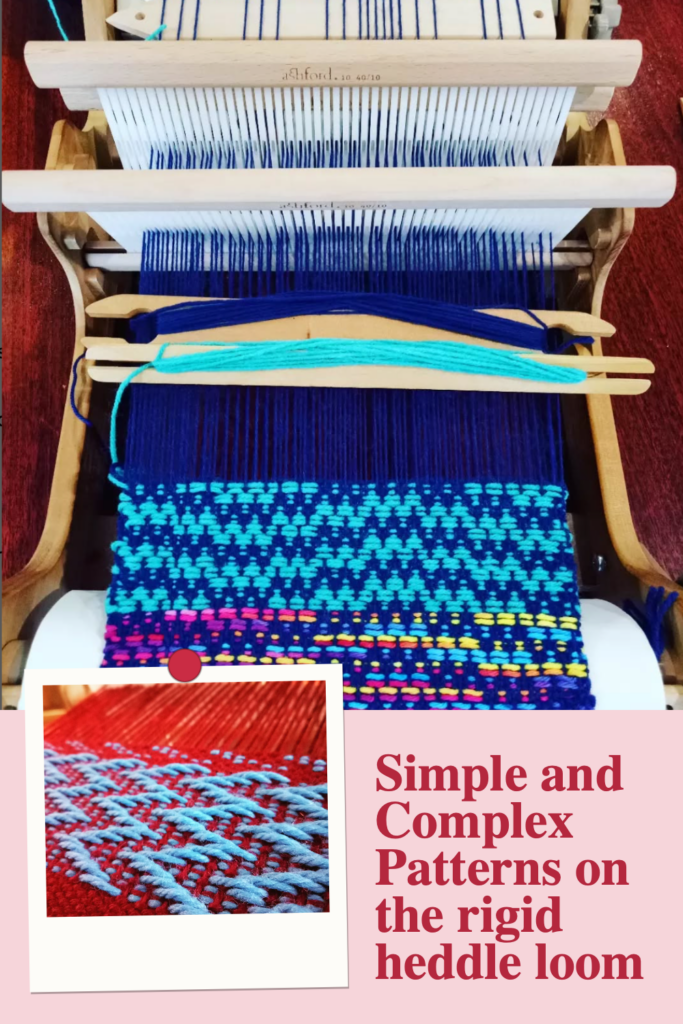

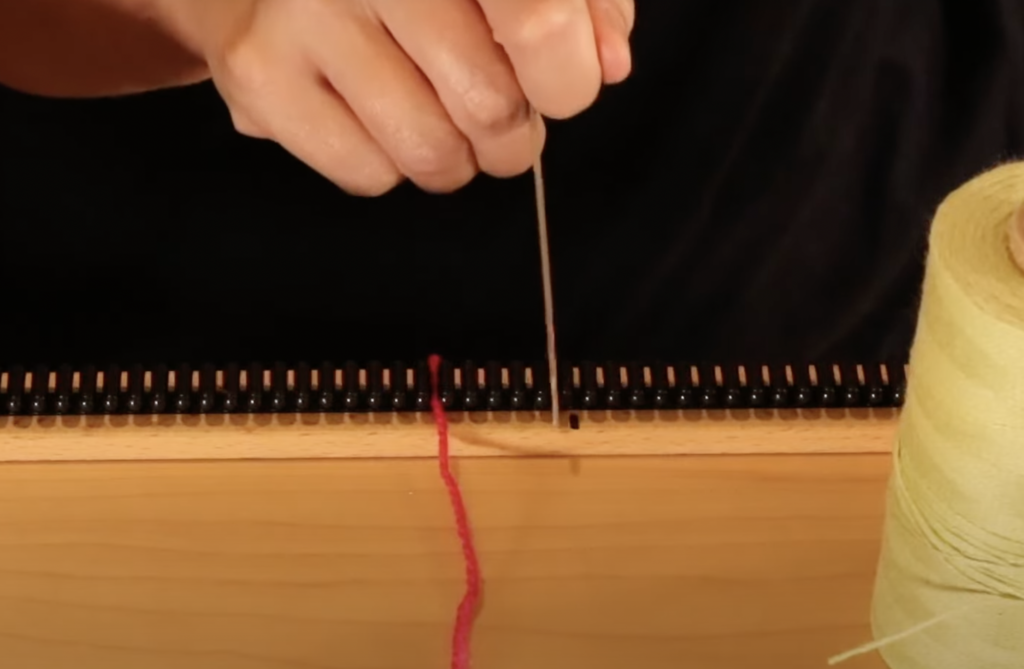

It is made of a lightweight wood, has 2 wooden heddles and wooden beater, and the warp is released and advanced by manually moving the back or front roller. A piece of wood, along with a cog hold the tension. These cogs slip very easily, so it can be difficult to achieve a decent tension, though this does seem to improve as you weave and advance the warp.

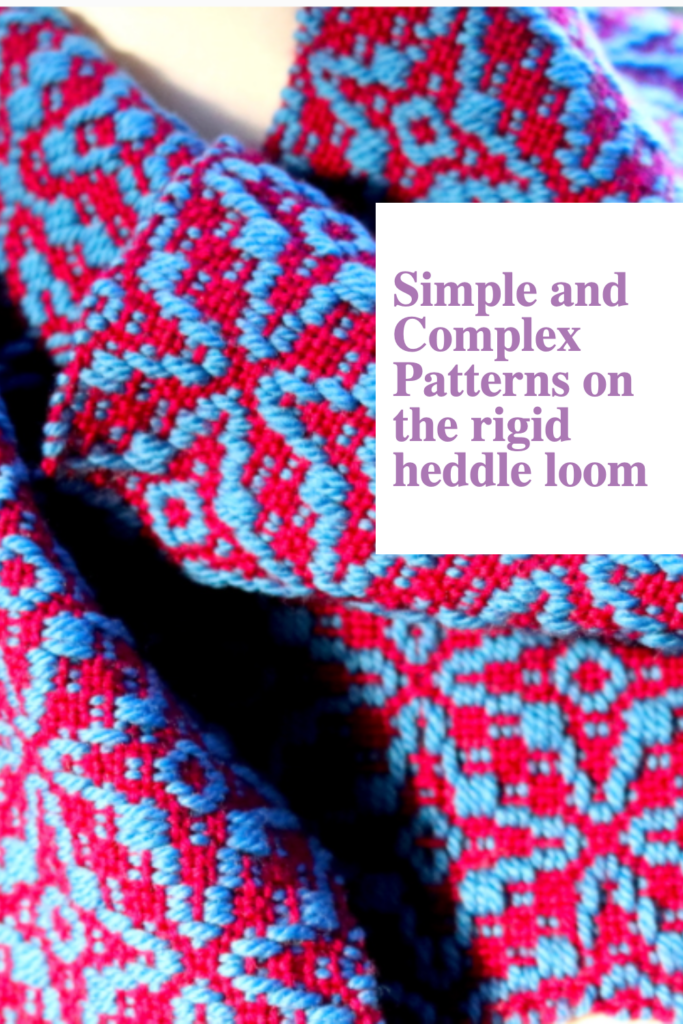

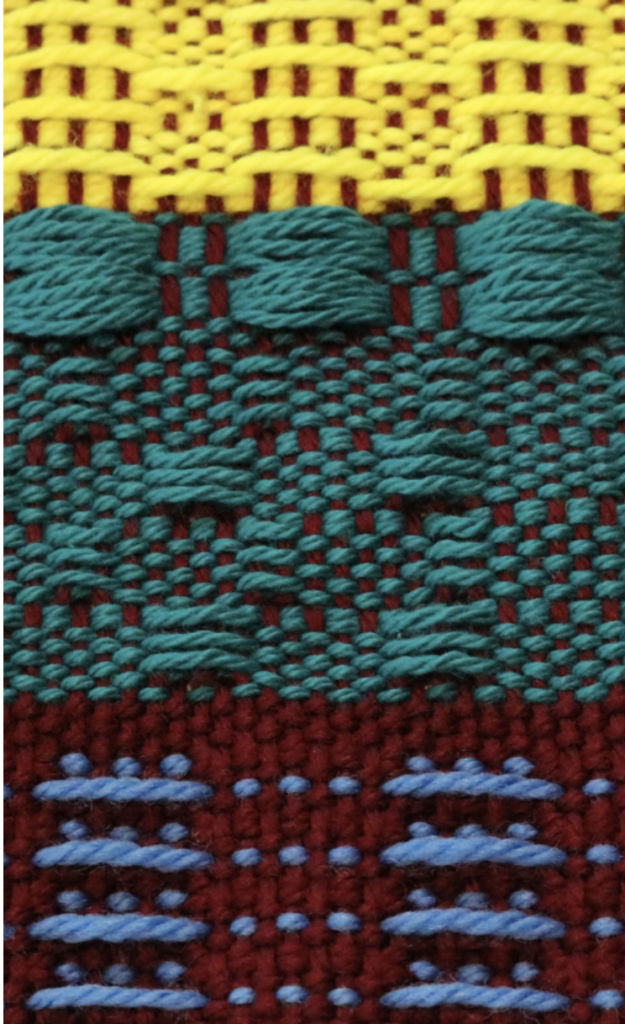

The heddles are similar to a rigid heddle, in that they have holes and slots. For the warp that came on the loom, they had it threaded through the holes on both heddles. The heddles are operated by rotating the top beam that both heddles are tied to, which causes the heddles to alternate in rising and lowering, providing two sheds to weave in and producing a plain weave fabric.

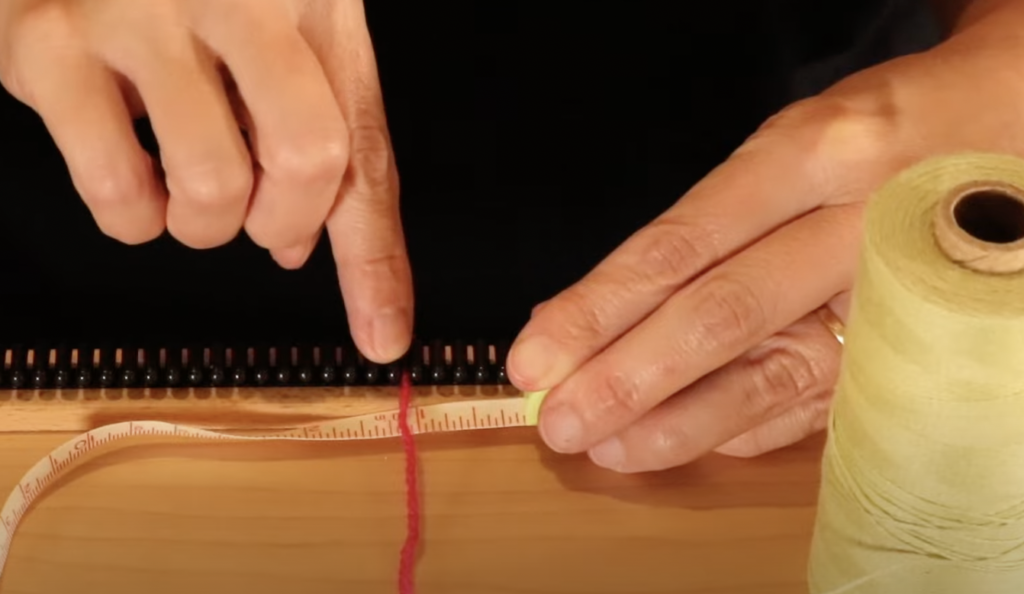

Upon measuring these heddles, I found that they are sized at 5 dents per inch – pretty wide apart for such a thin warp. So, when you weave, you get quite a weft faced fabric and it’s better to beat gently to avoid the fabric being too dense (unless of course, you really want a weft faced fabric).

The most frustrating aspect to using this loom was the tension. The warp that came on the loom was very loose in some sections. It seems that the loom is probably not strong enough to hold really good tension but I want to experiment with this further in the future by warping it myself.

The maximum weaving width is around 5.5″, so definitely only a small item loom – again, great for kids who might want to weave doll’s blankets or squares to sew together to make a larger item. Some adult weavers have also told me that they use this loom for sampling for larger projects.

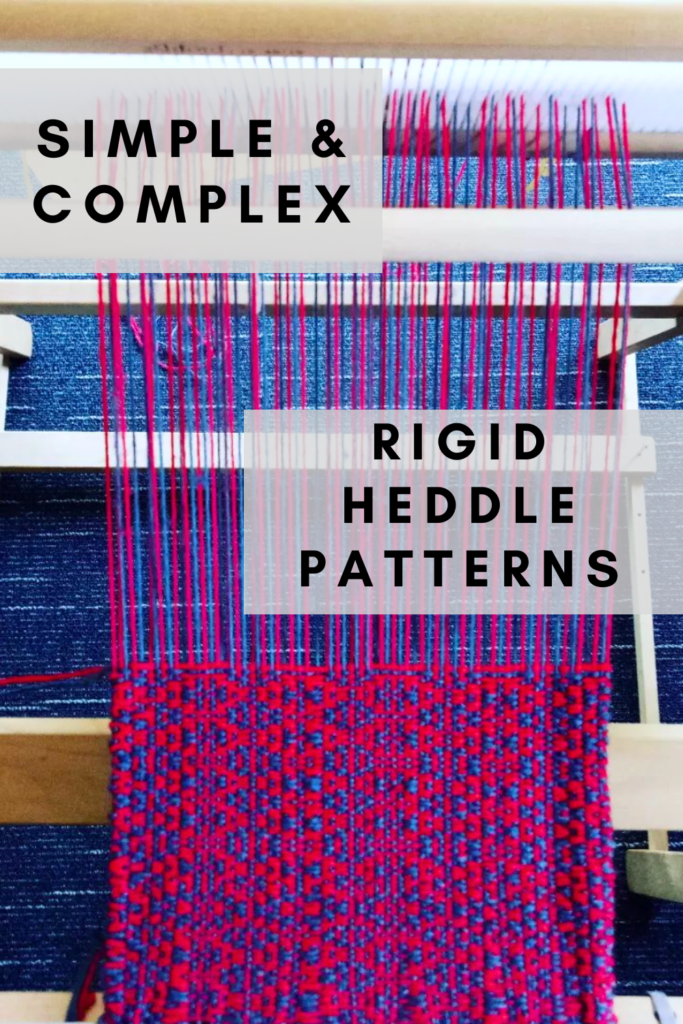

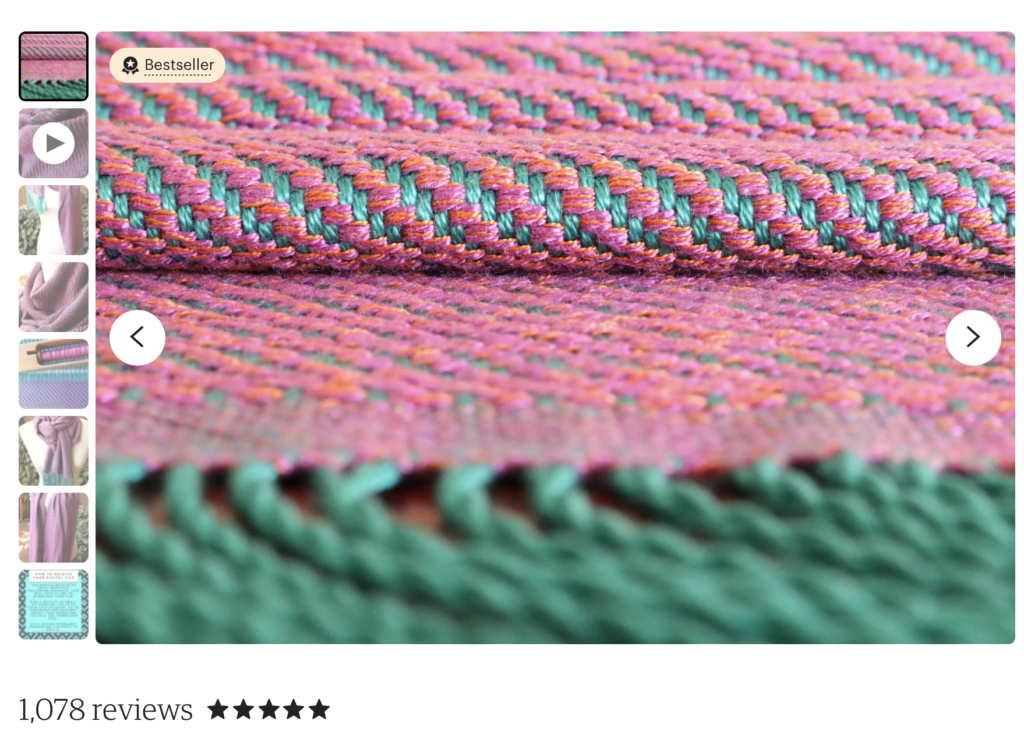

While I found this a fun little loom to weave on, there is definitely a lot of room for improvement! My plan to move forward with it is to re-warp it with a thicker yarn, possibly thread the heddles differently and then to play around with pick up sticks to increase the shaft possibilities.

What I would recommend though, is that if you are serious about getting into weaving, save up the extra money to buy a quality loom. Something like the Ashford Sampleit is a really great place to start, and you won’t have to worry about not achieving good tension or possibly breaking parts.

If you would like to see me unpacking, setting up and weaving on this toy loom, watch this video:

Since writing this article I have used this toy loom more extensively. My experiments lead me to replace some parts of the loom, re-warp the loom and weave some pick up on it. To learn more about that, please see this video:

Until next time…

Happy Weaving!