In my last post, I spoke about my back pain journey and gave all my best hints to help you avoid experiencing pain while weaving on your floor loom.

That post was very popular and many of you asked if I could do something similar for weaving on your rigid heddle loom. A floor loom and a rigid heddle loom are quite different when it comes to seating, and while a lot of the same principles I talked about in my last article regarding posture still apply, I think it’s worth going over the options.

*This post contains affiliate links. For more details, please see my disclosure policy.

I’d like to point out that, even though some of these are not my personal preference, that doesn’t mean that they’re not right for you. And, if you are using a seating arrangement currently that works really well and allows you to weave pain free – don’t change it!

Regular chair-

Some weavers use a regular, straight backed dining chair to weave. This is what I started off with when I began my rigid heddle journey, but it did not suit me at all. I did find it better if I bolstered my lower back by wedging a cushion between my back and the chair when weaving, but it was still not comfortable for me.

Weaving bench–

I would not use a weaving bench or piano stool with my rigid heddle. The length of the stool does not allow me to get right in close to the loom, and there is no back support.

Office chair–

This is what I use and I’m going to go over in more depth why I think it is the best option in a moment.

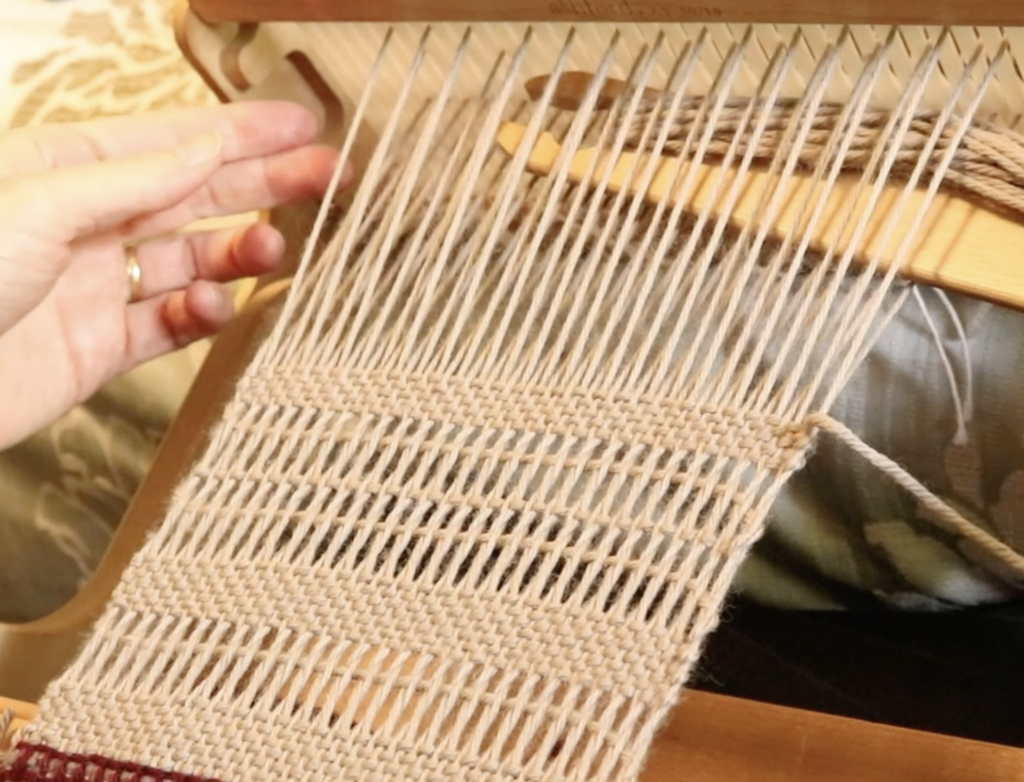

With a stand-

I do recommend weaving with a stand for loom sizes 24″ and above. This is because the larger/wider the loom, the more difficult it is to prop against a table to weave, and the longer your reach distance will be. A longer reach distance means more stress on your body.

Without a stand-

I don’t use a stand for my Sampleit 10″ loom because it’s so small, light and portable that I can weave on it just about anywhere, it makes a great lap loom. You don’t have to have a stand for your rigid heddle, but I do think it’s really worthwhile investment. If you have or are looking at purchasing a really large loom, such as a 32 or 48″, I would definitely be wanting a stand.

I want to talk now a little more about my office chair and why I think it’s the perfect solution. I was lucky enough to get my chair for free when my husband’s workplace was closing an office and it was barely used!

- Height adjustable

- Contoured

- Back rest adjustable

- Tiltable

All of this means that I can sit right in close to my loom and adjust the chair to be as comfortable as I could possibly want to be. My back, shoulders and neck are not stressed because my body is so well positioned.

Because my chair is on wheels, it’s really quick to make minor adjustments to get closer to or further from the loom.

My feet are either flat on the floor or positioned on top of the stand’s stabilising bar, meaning the loom is very stable.

Now, just because we have a super duper chair with nice back support doesn’t mean we can get lazy about posture. Yes, it’s still possible to slouch, bend or tilt your body in ways that will wear on your back over time.

So don’t forget those good posture points – a straight back, level shoulders, elbows resting comfortably on the front beam.

Regular breaks are important, to give your body an opportunity to move about in a different way after being in one position for a while. If you want to read more about posture, breaks and stretching, I recommend you read over this post.

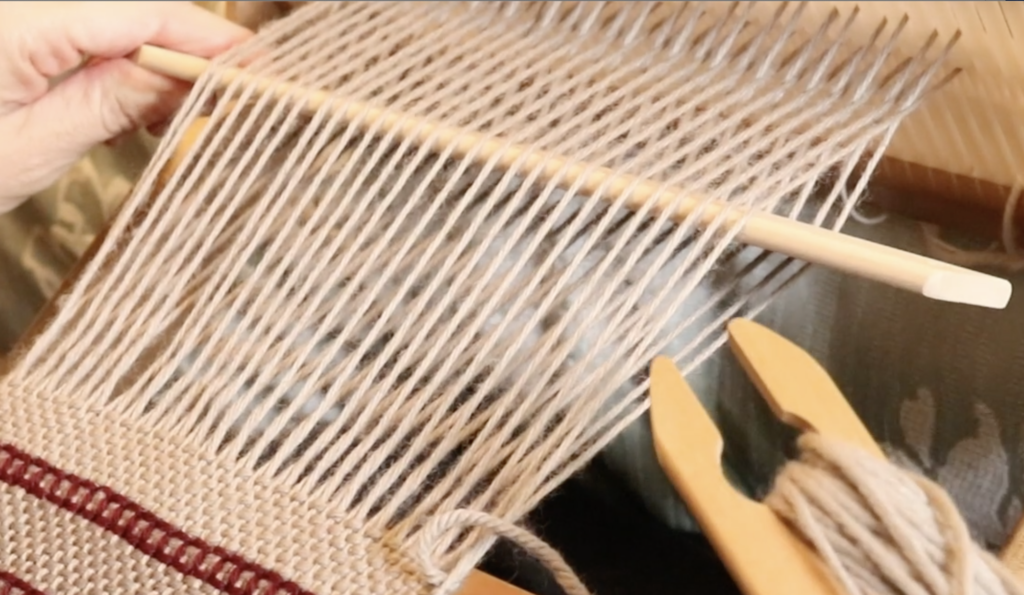

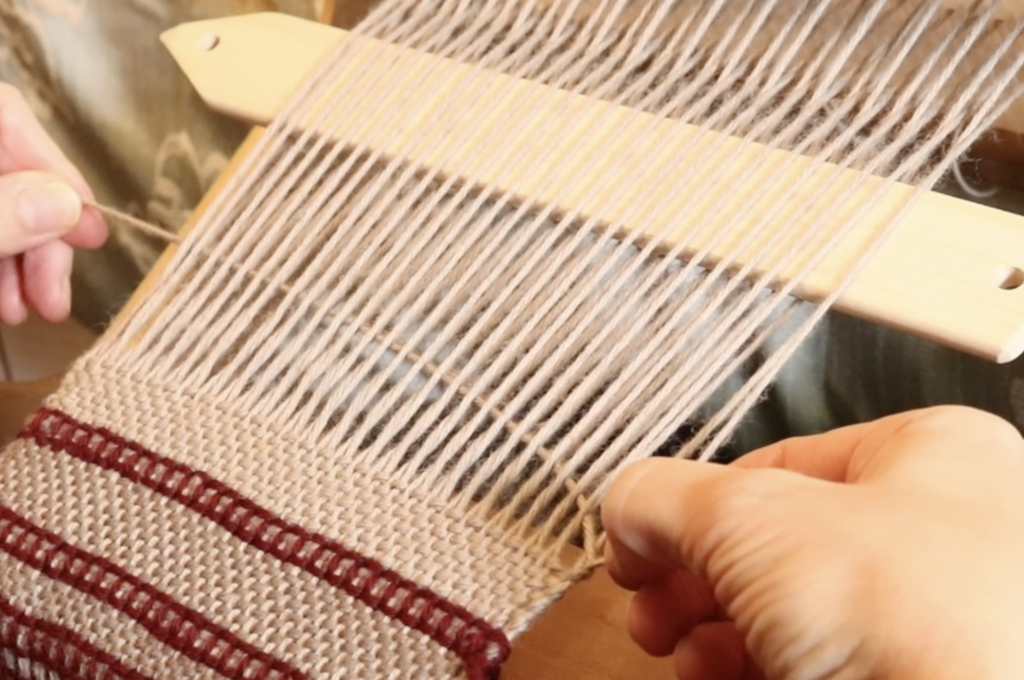

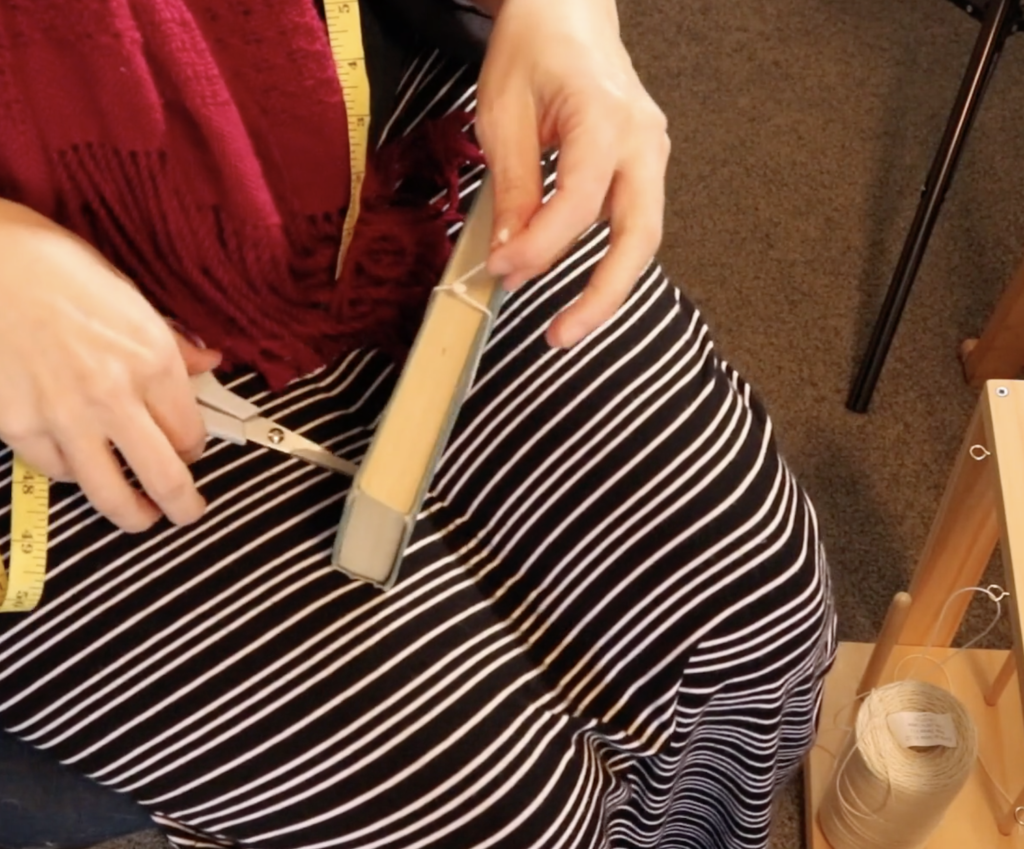

And to see my seating position in action, I’ve made a video for you. The video shows both how I sit with my loom on a stand and how I sit when not using a stand. You can click below to check that out:

I hope this post was helpful to you and gets you thinking about ways you can maximise your weaving time by minimising back, neck and shoulder pain.

Until next time…

Happy Weaving!